DELIVERY TERM

Our manufacturing capacity allows us to place orders in record time and reduce delivery times of up to 14 days. All shipments are made by the most trusted transport agencies, this prevents possible losses or delays of merchandise.

HIGH PERFORMANCE

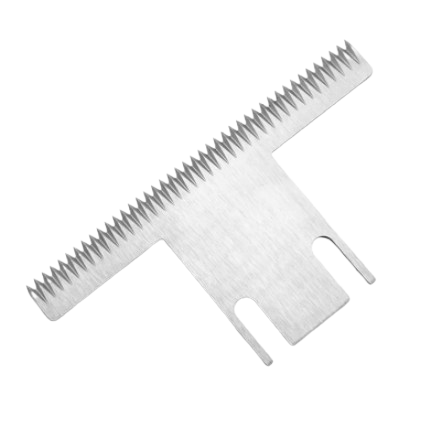

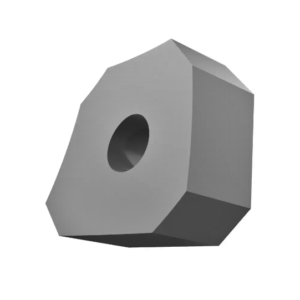

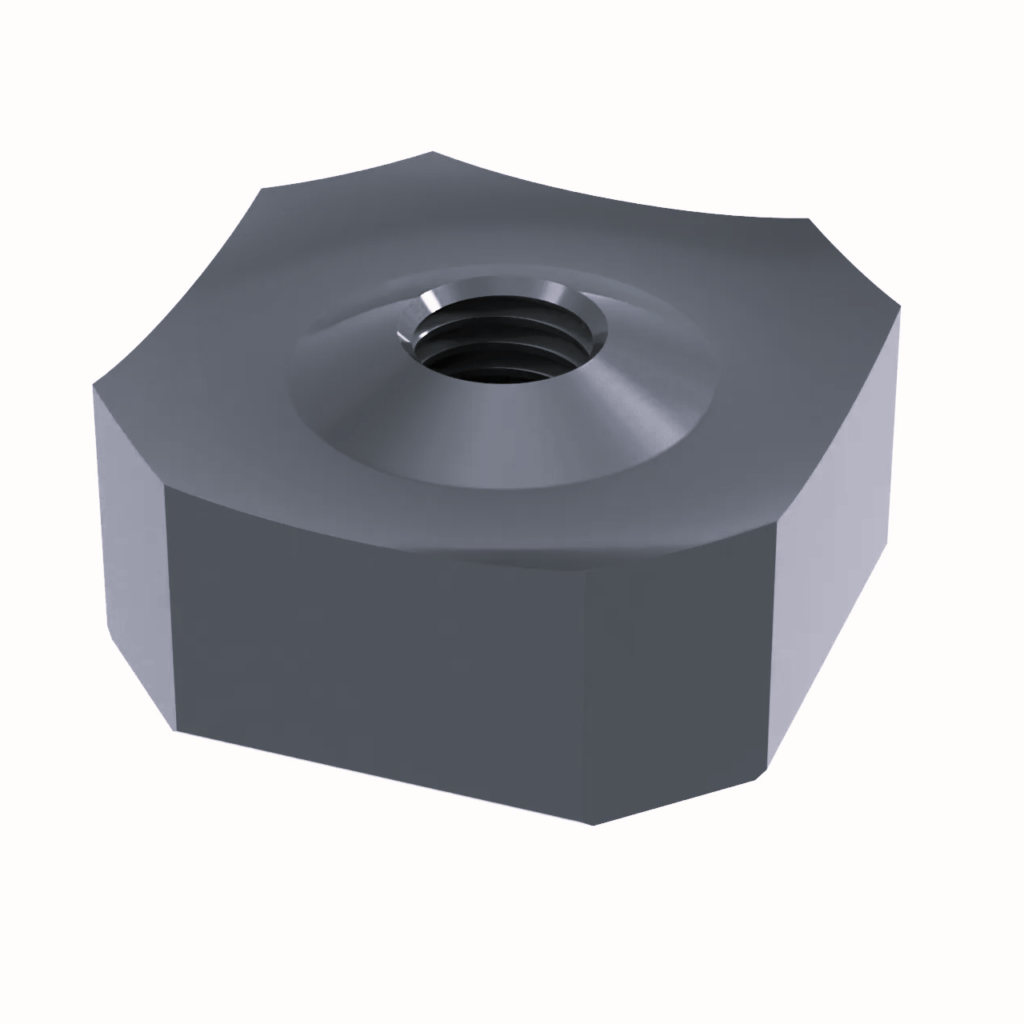

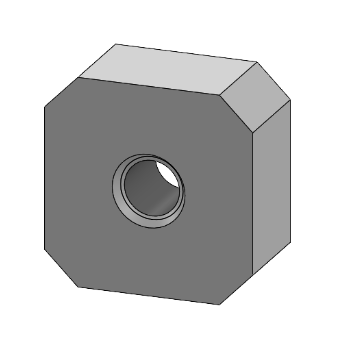

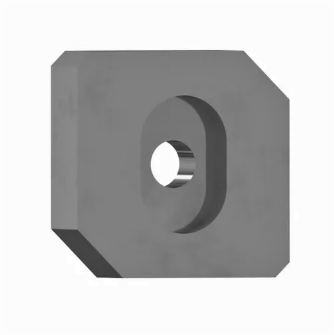

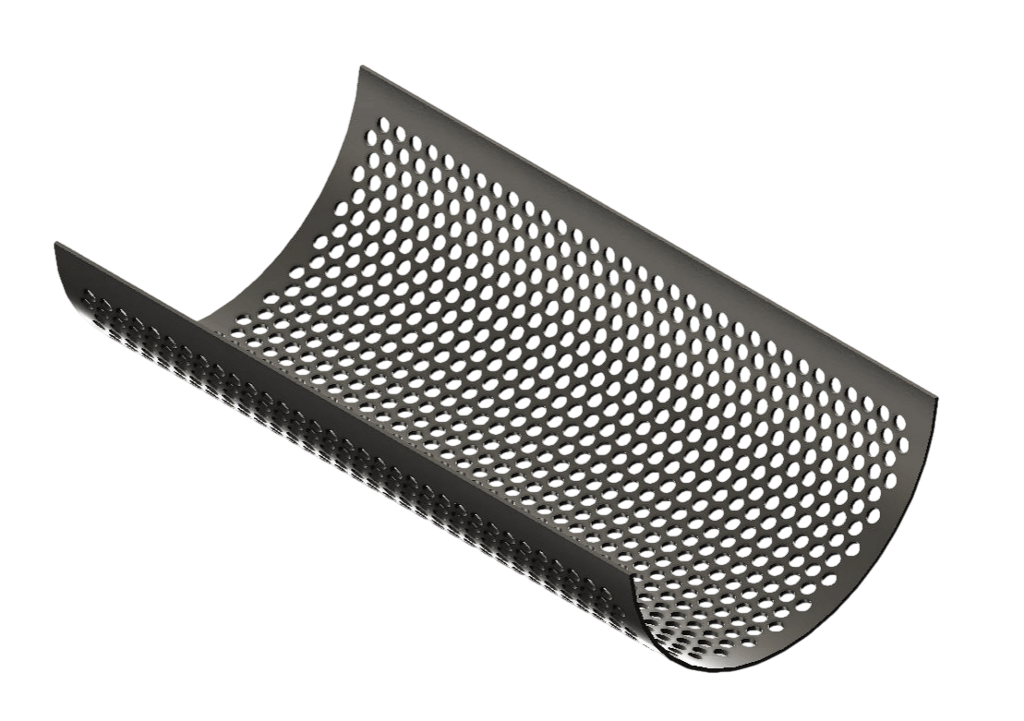

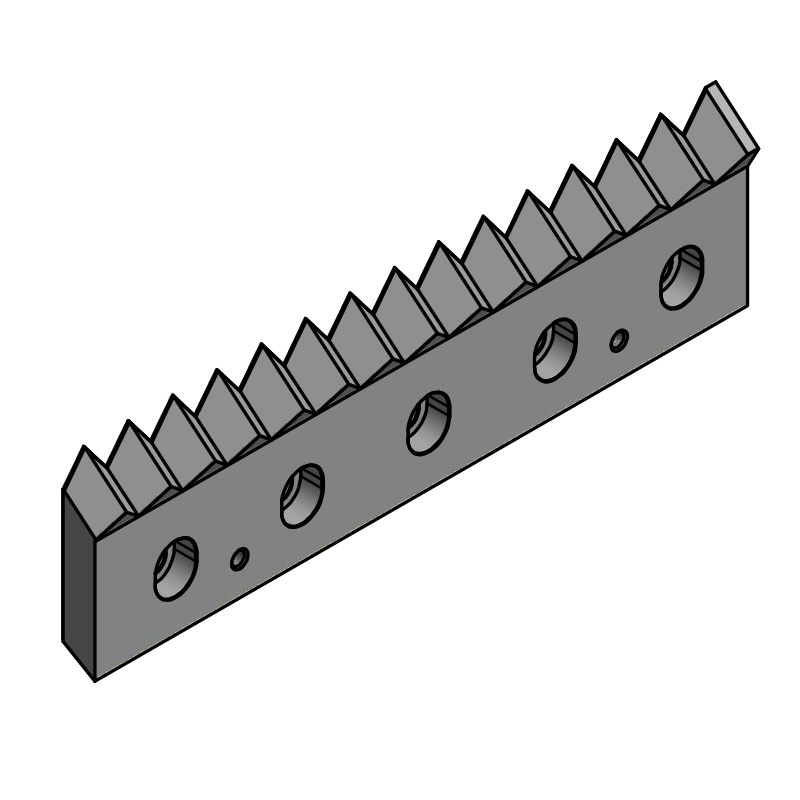

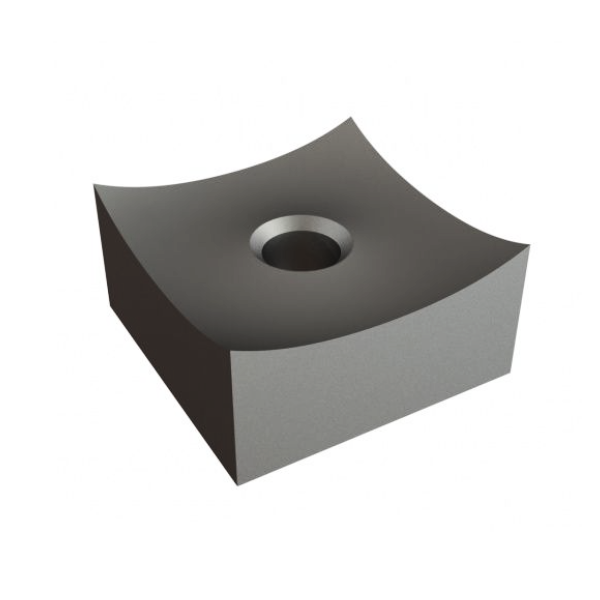

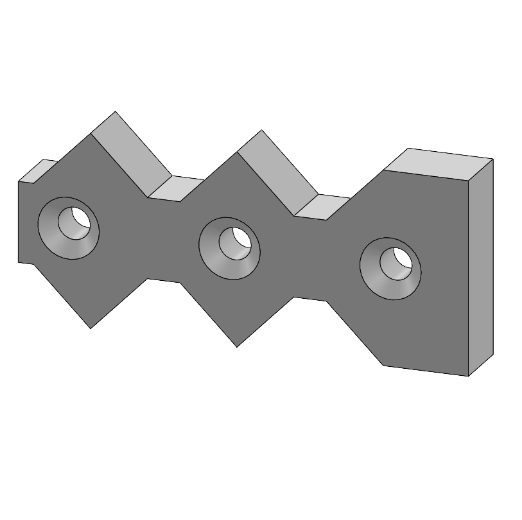

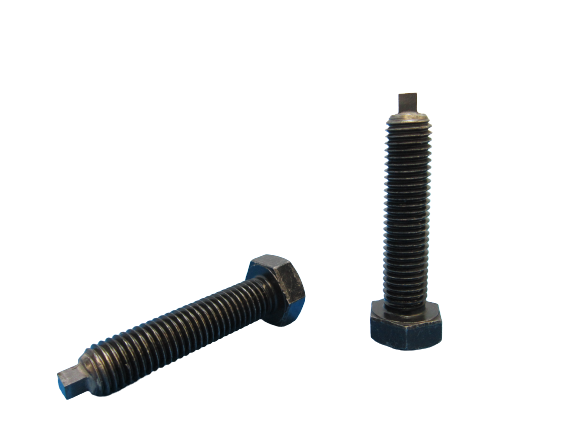

In our production we only use high quality steel and each of our products goes through a process of heat treatment in vacuum furnaces. This guarantees consistent hardening throughout the part and ensures the most efficient operation in the harshest environments.

COMPETITIVE PRICE

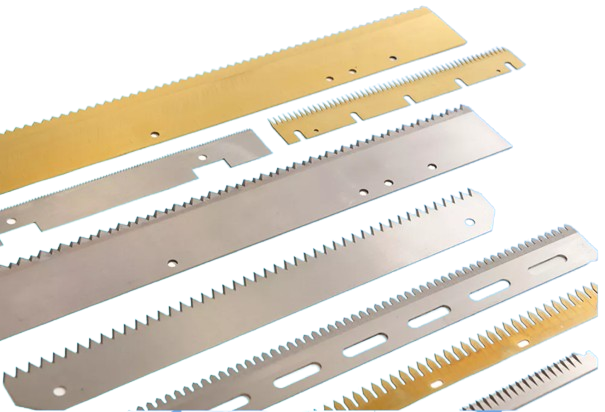

We offer industrial blades at the most competitive prices in the market.

Thanks to modern manufacturing technology and high product quality, our customers are able to prolong the production cycle and in turn save on sharpening and replacement costs.

FABRICATION PROCESS

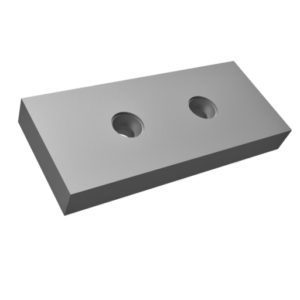

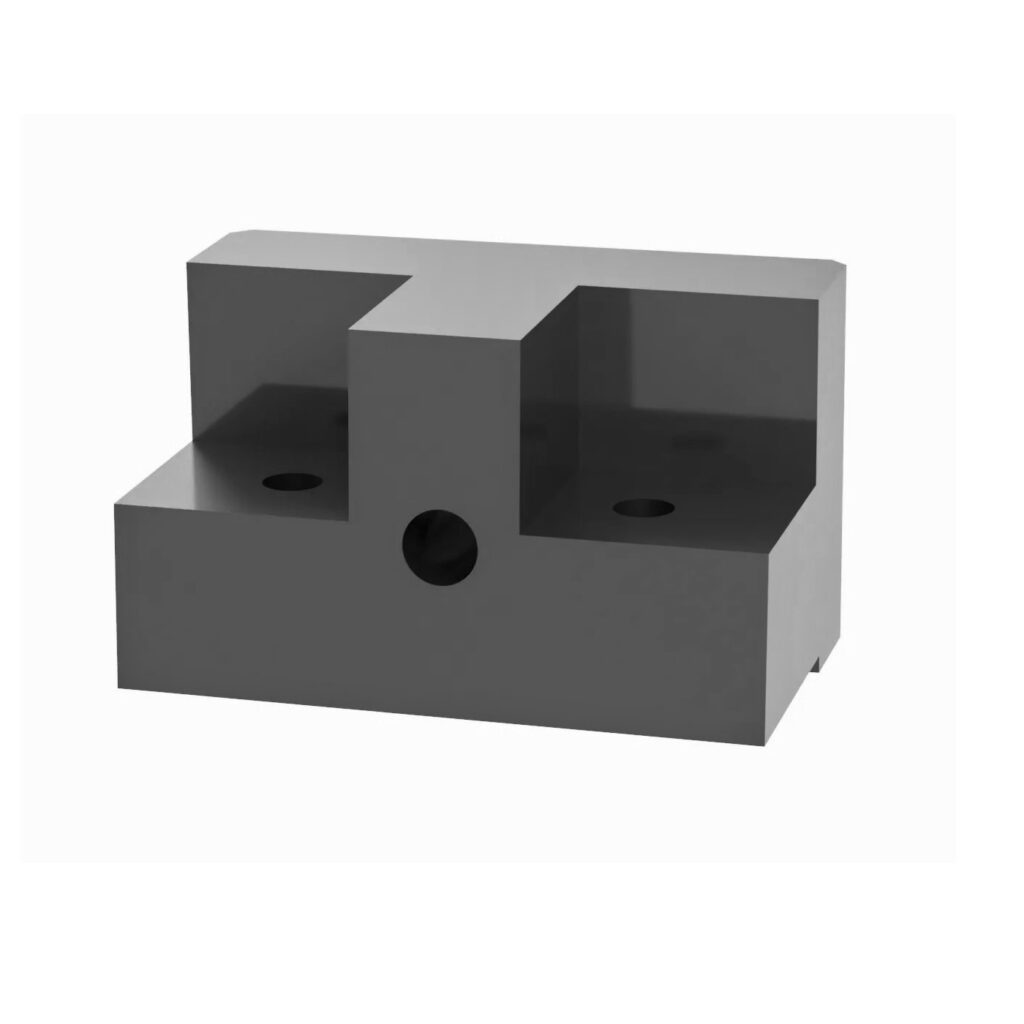

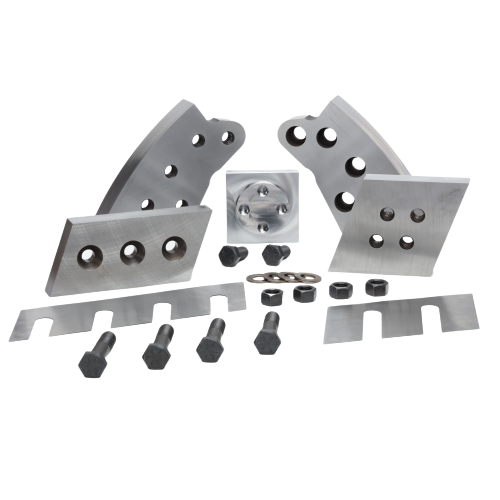

We combine state-of-the-art machinery with traditional manufacturing to achieve a high-precision end product of the best quality.

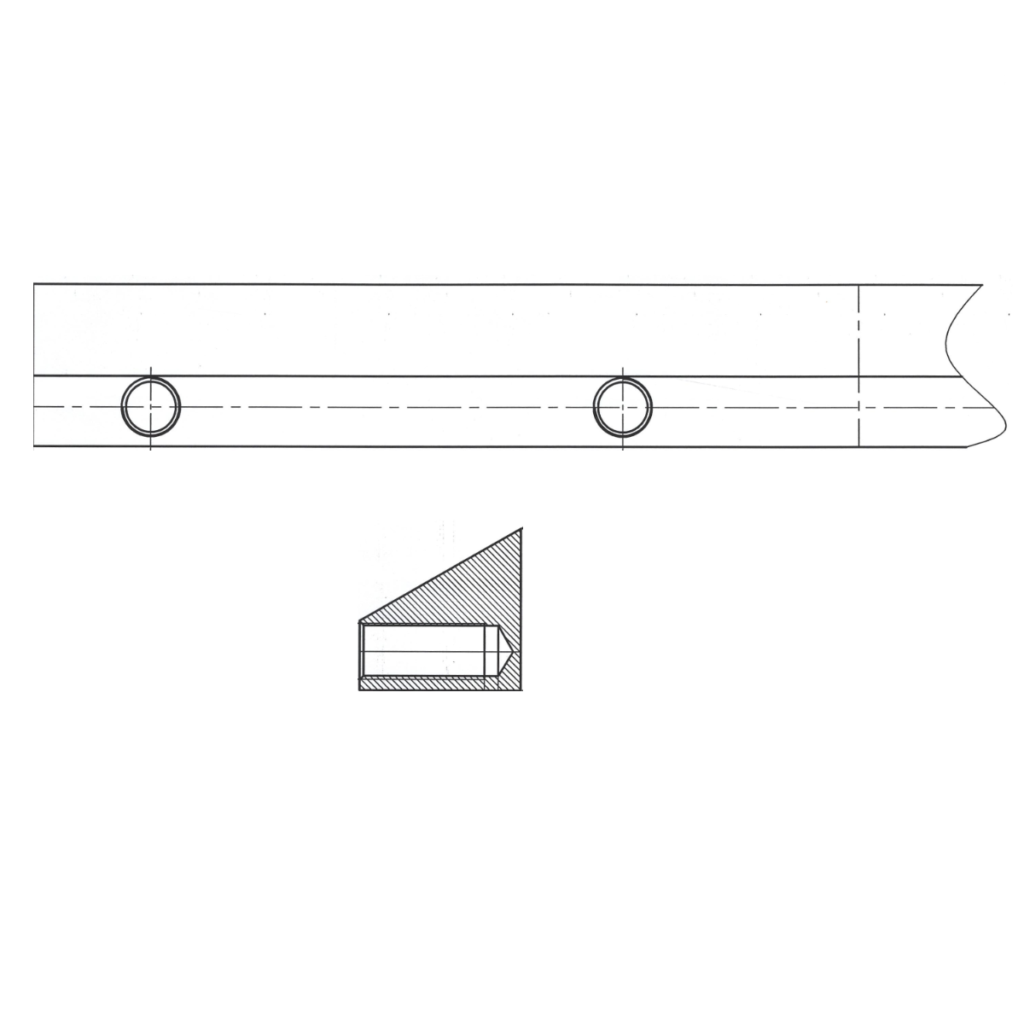

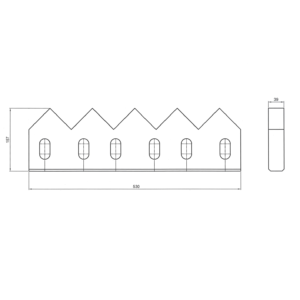

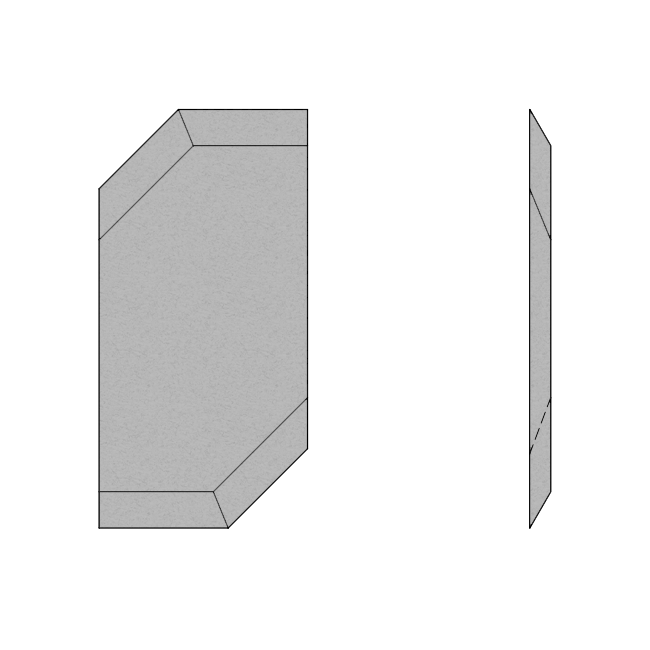

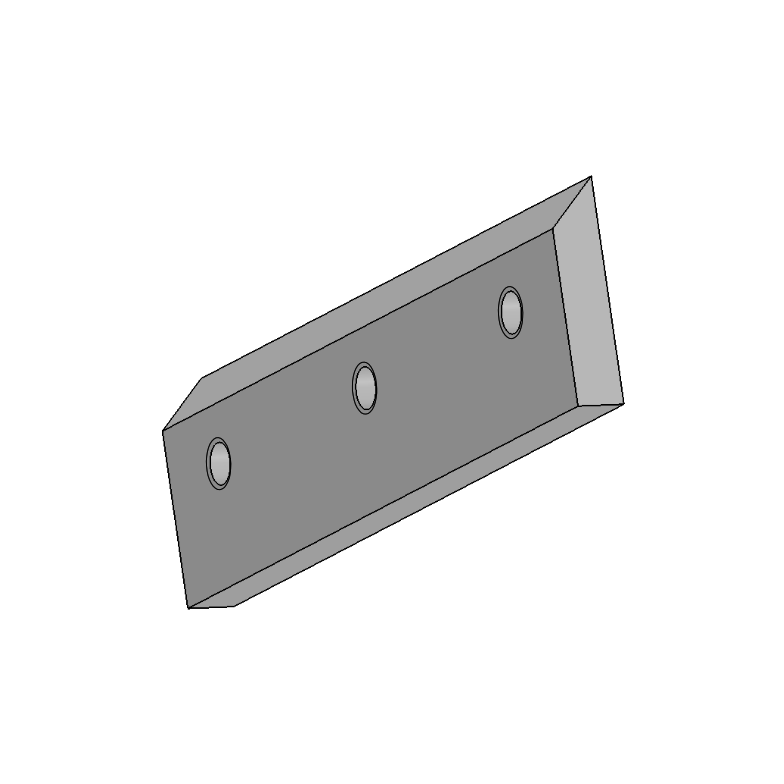

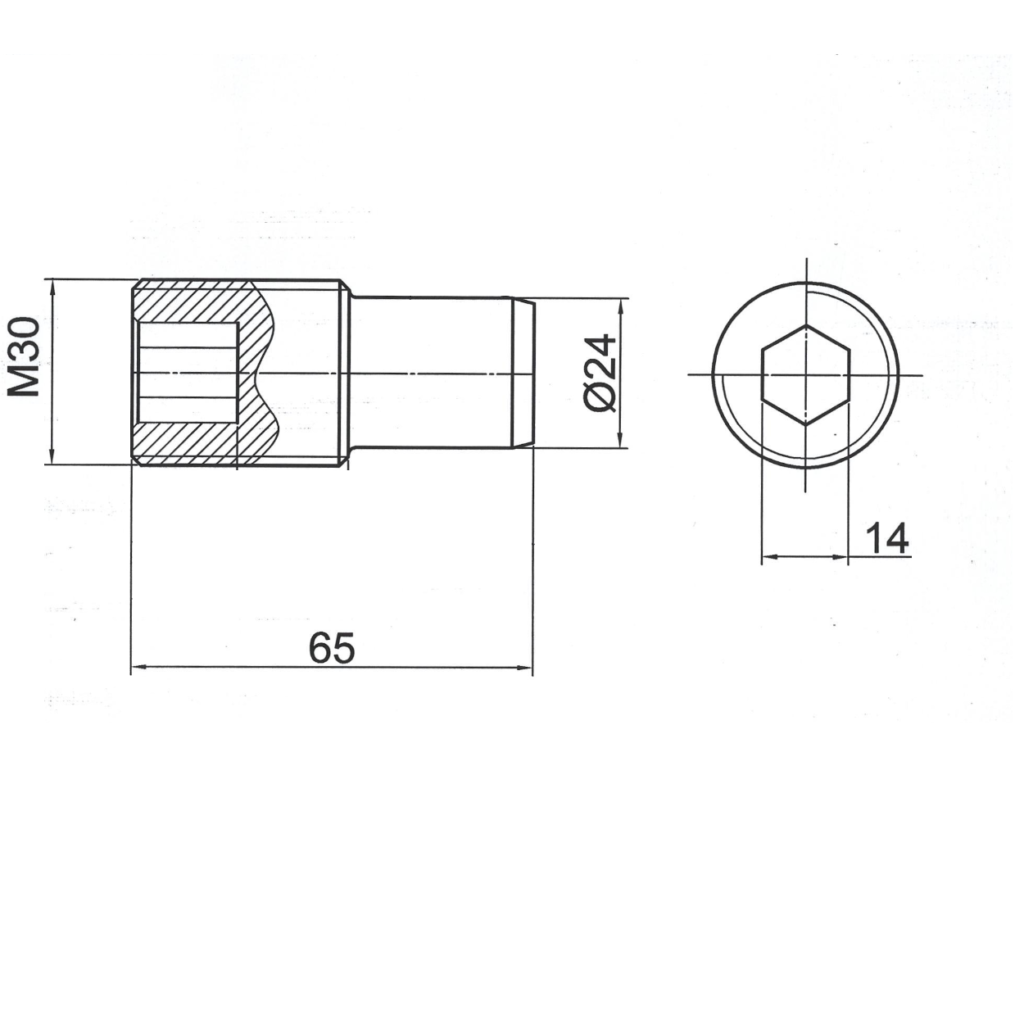

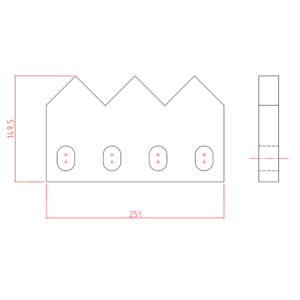

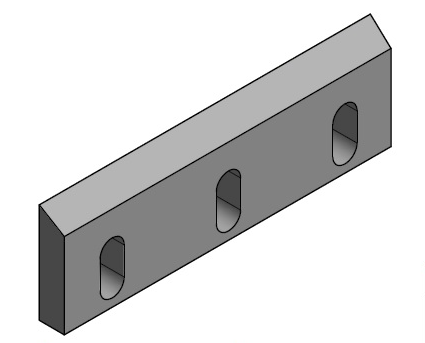

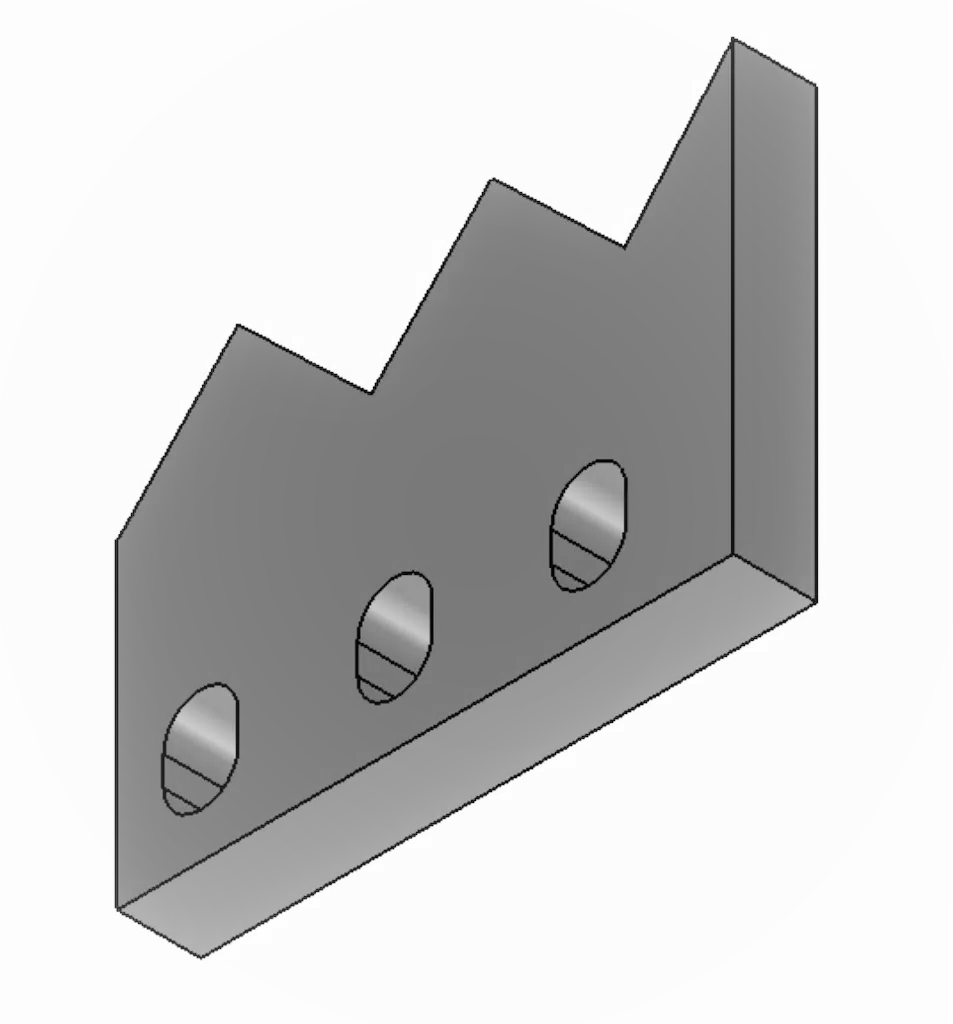

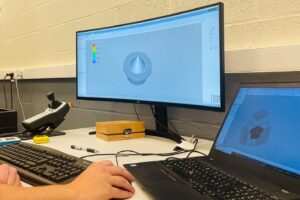

Design

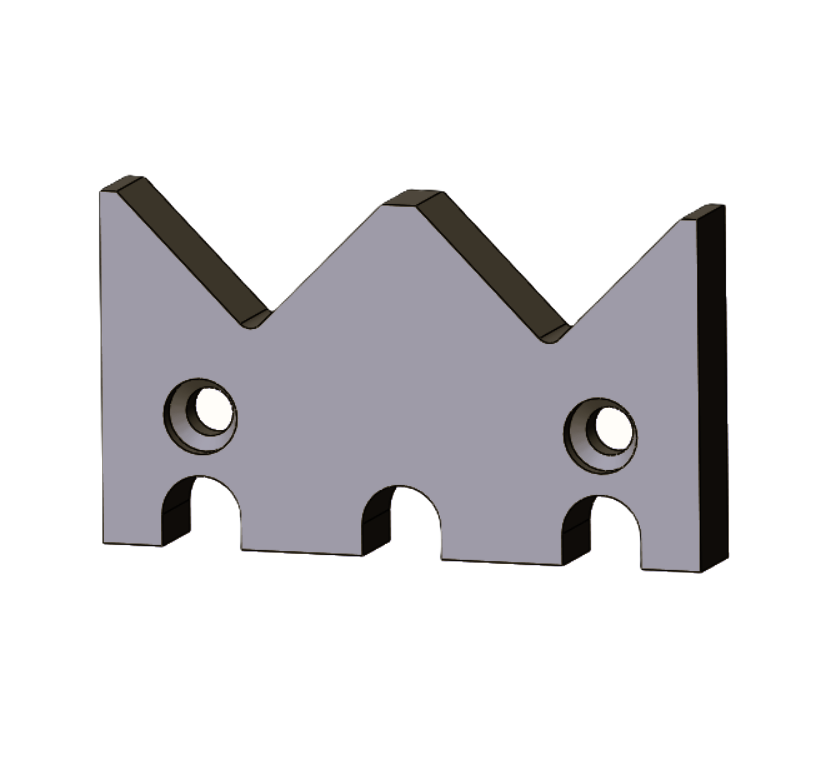

We put our Engineering Department at your disposal to design, adapt and build the blades that suit your needs.

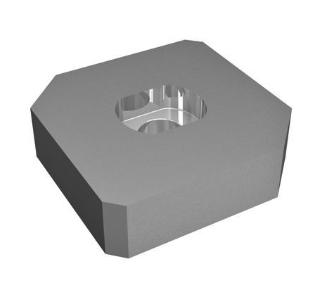

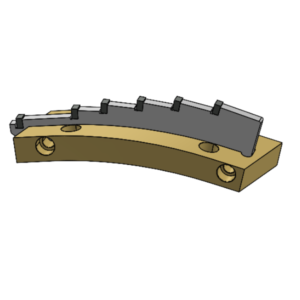

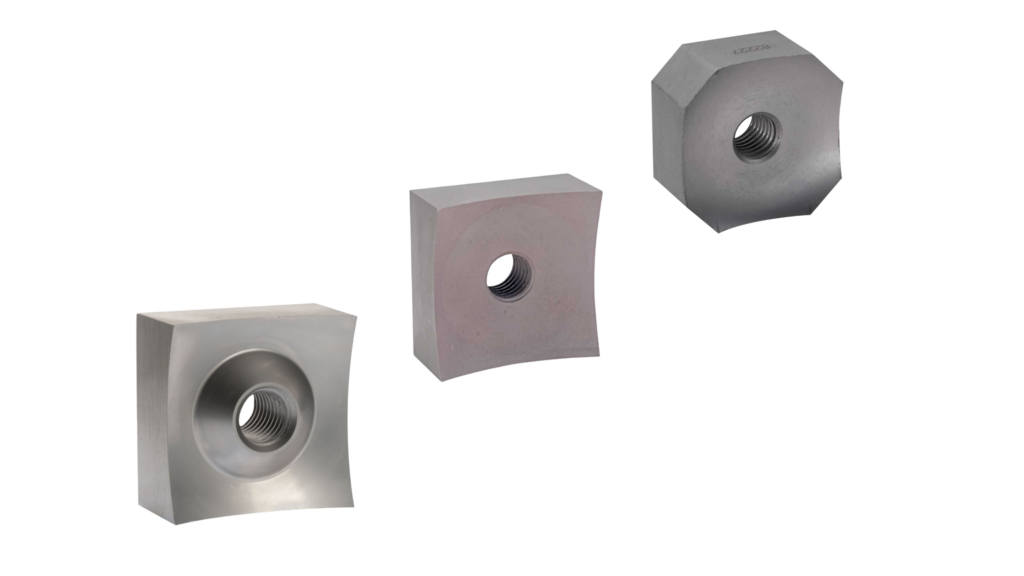

Selection of materials

We have a large stock of steel to be able to offer short delivery times and choose the most appropriate grade for each particular process.

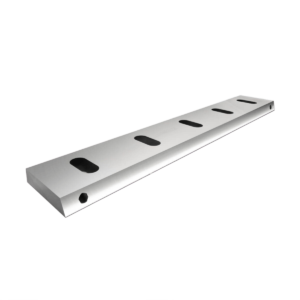

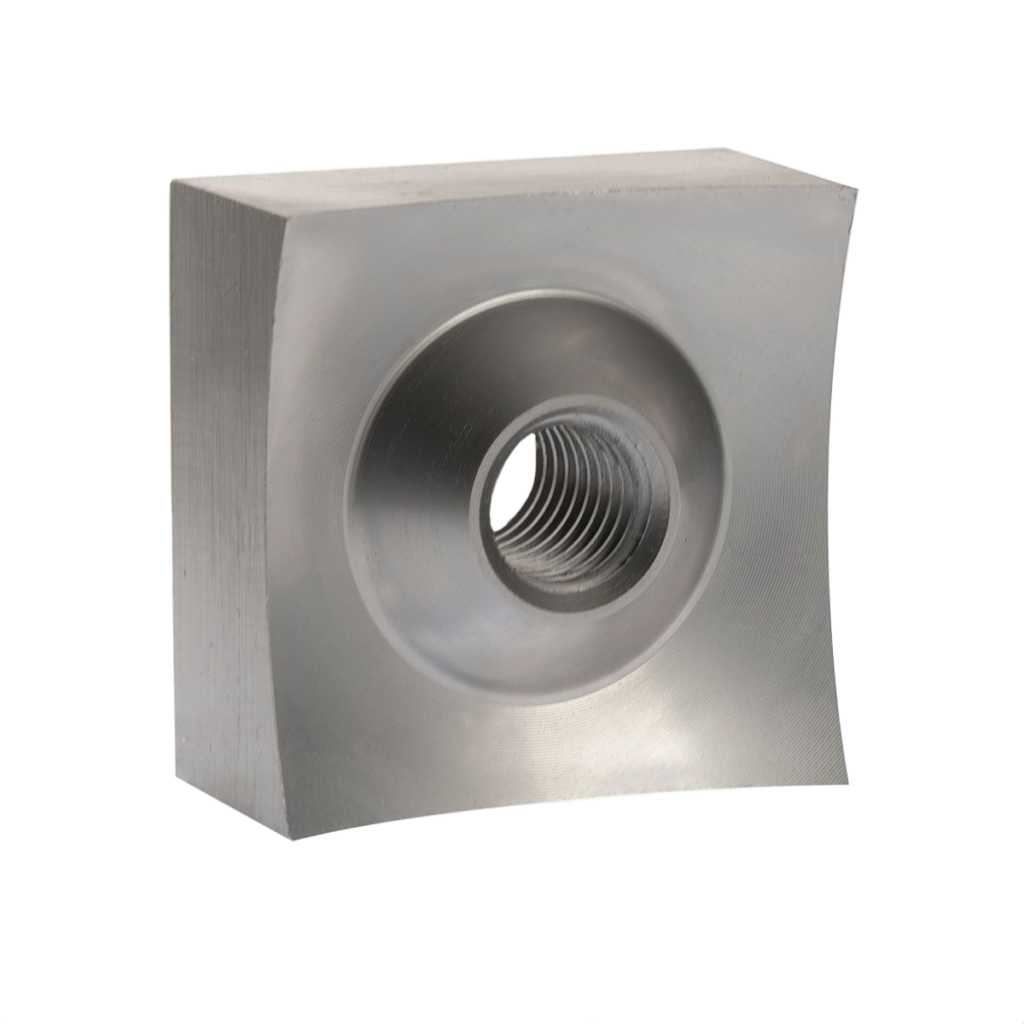

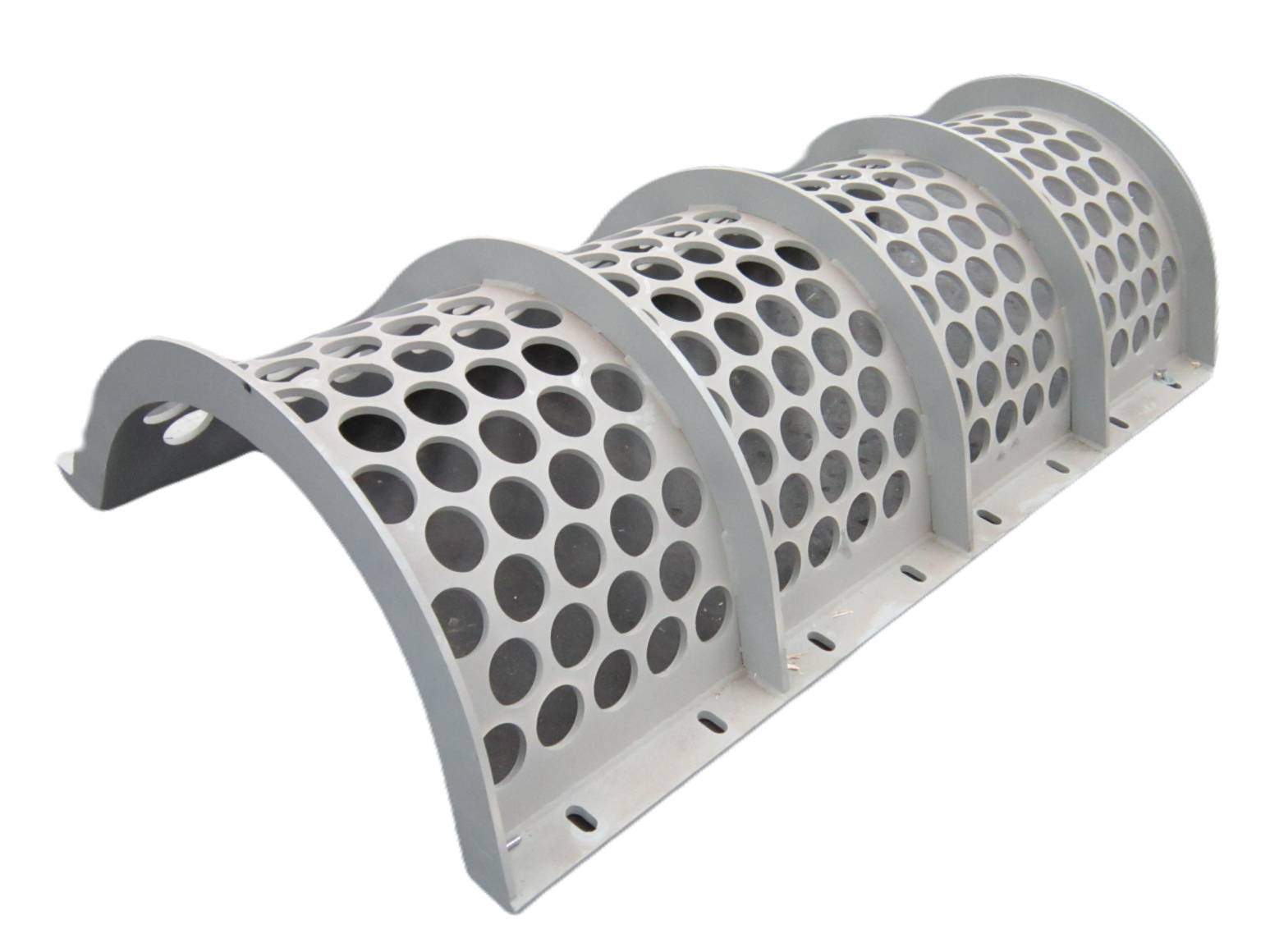

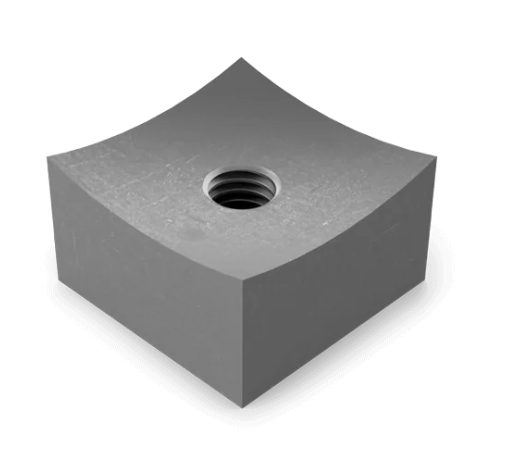

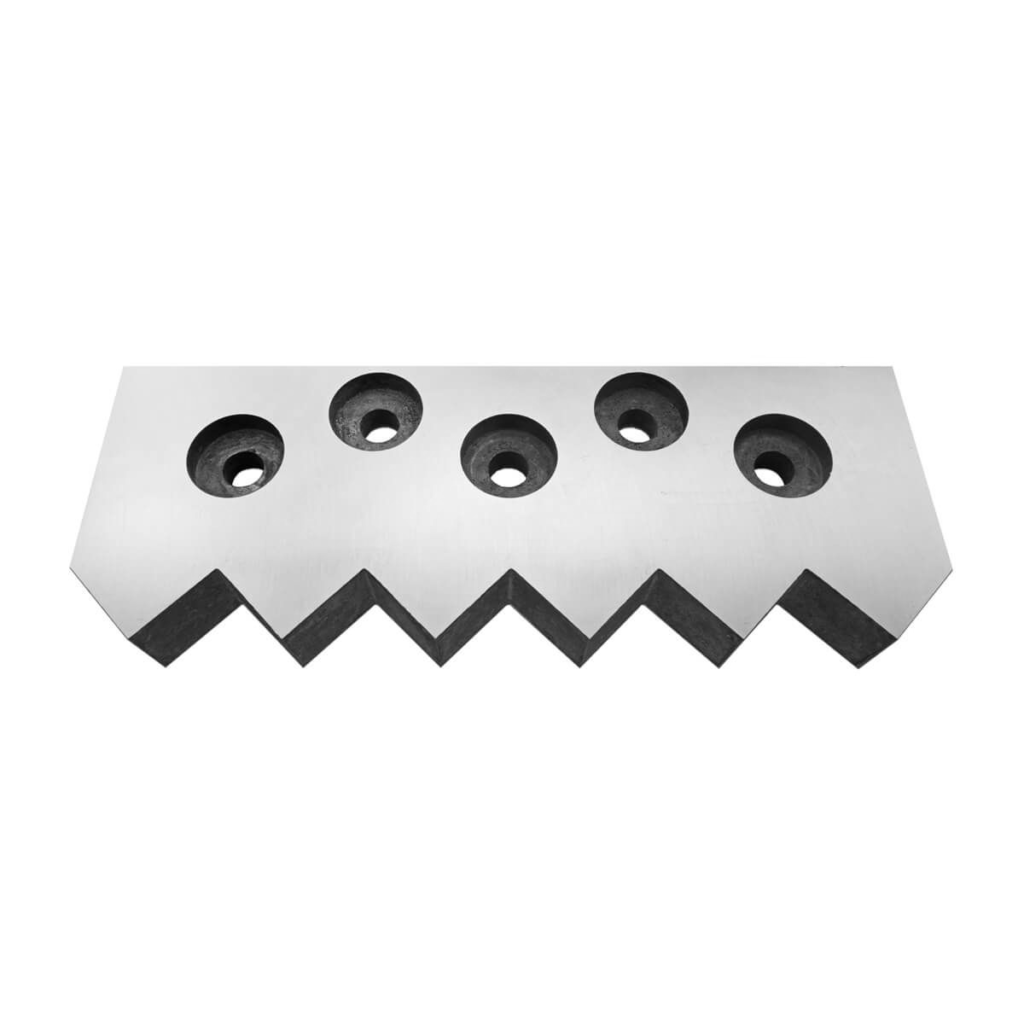

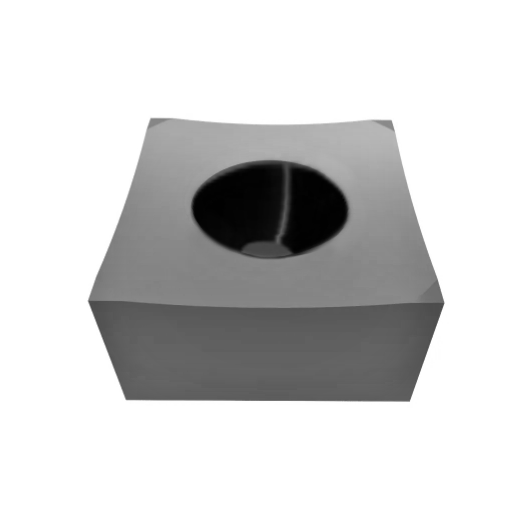

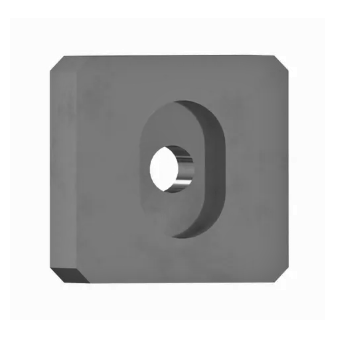

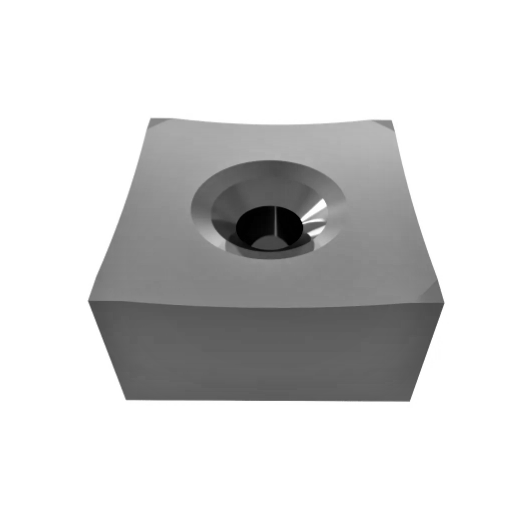

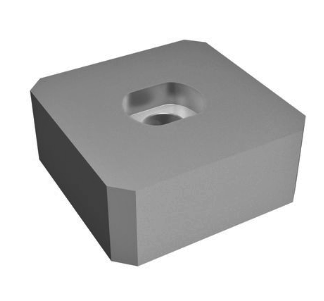

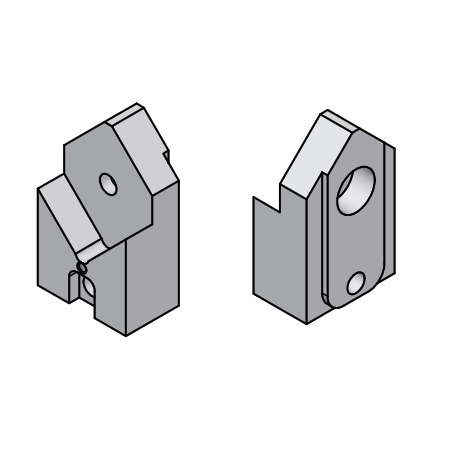

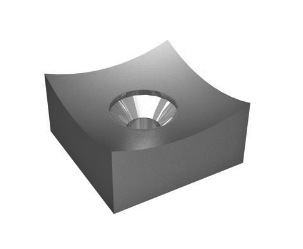

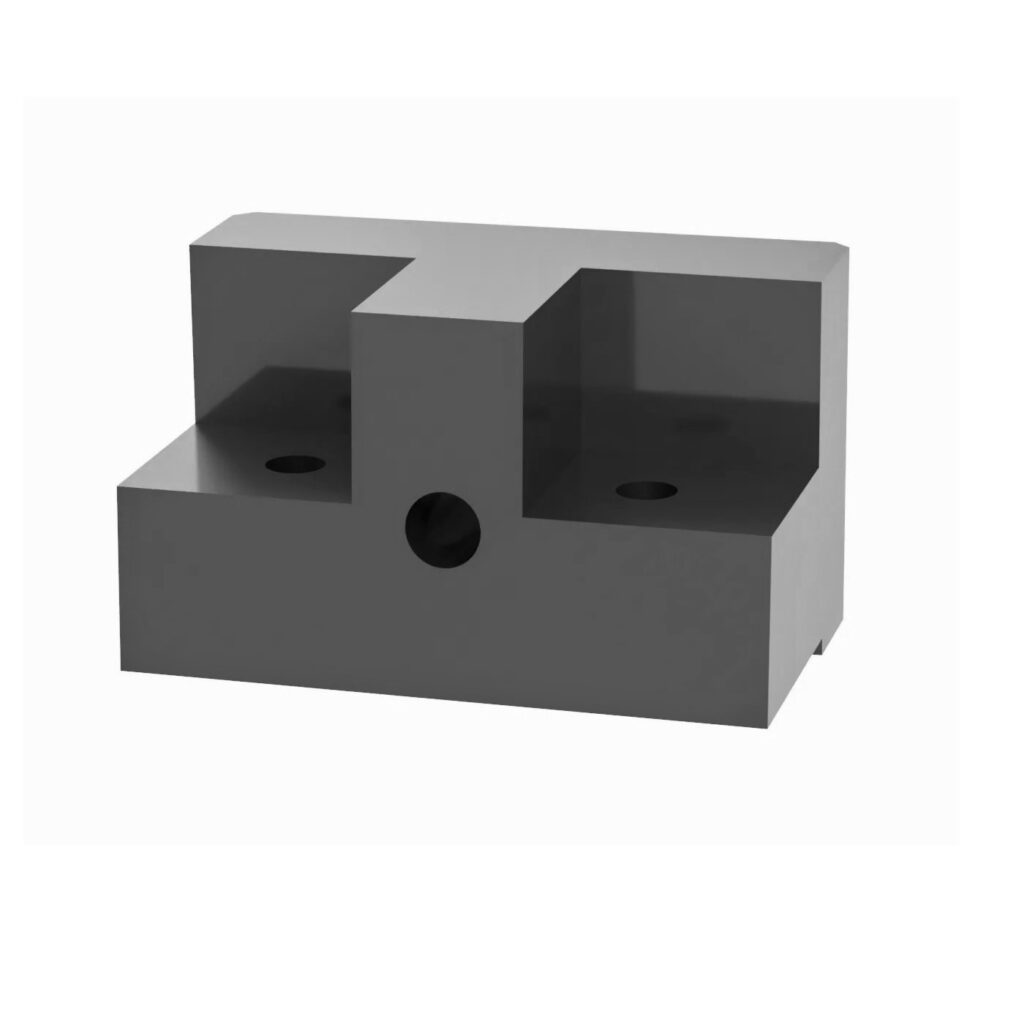

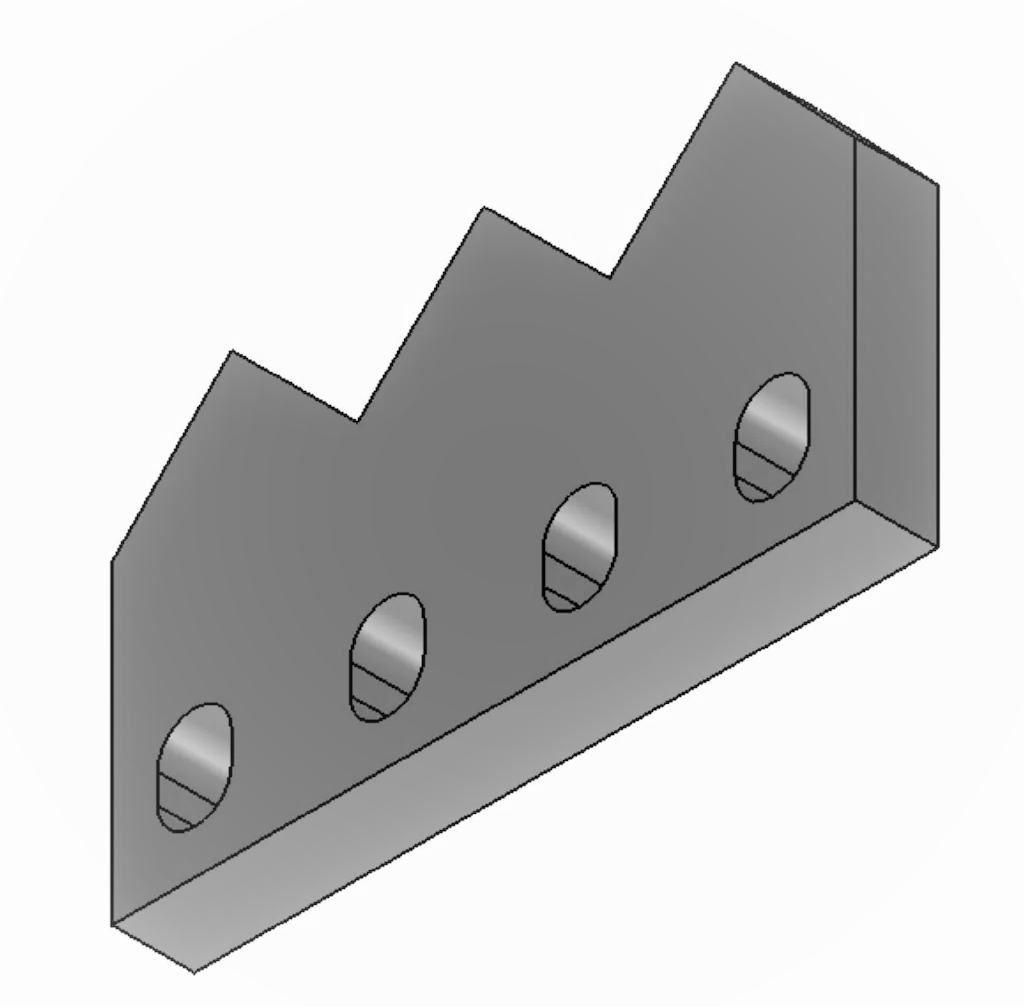

Precision machining

For precise and high-quality production, we use the most modern equipment on the market.

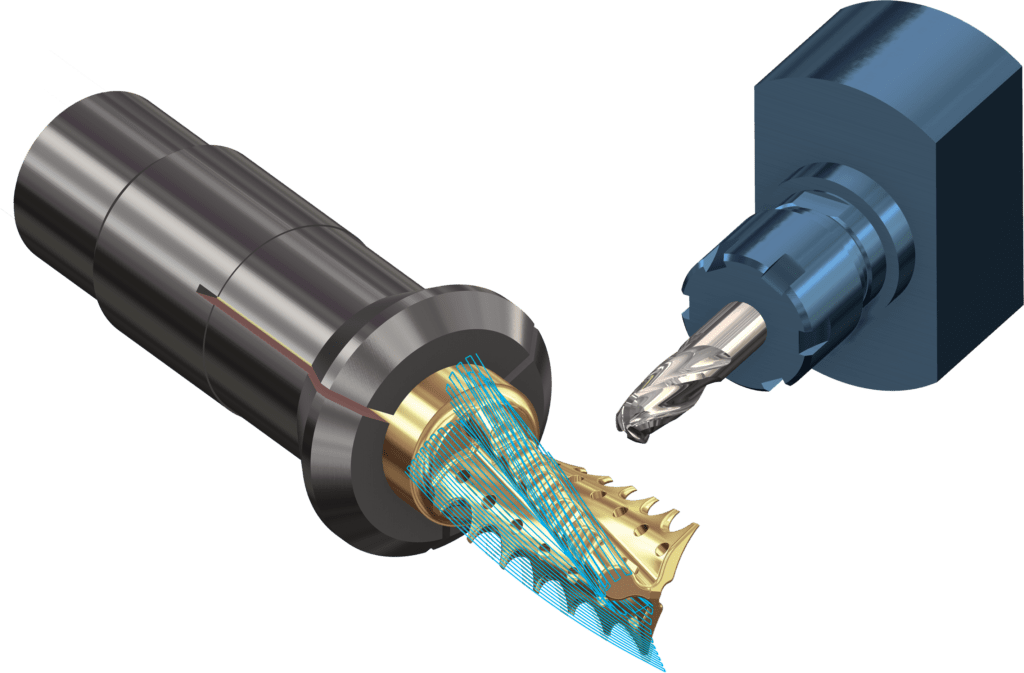

Heat treatment

We have many years of experience in the heat treatment of special steels. Our equipment is automated and has the most appropriate treatment programmed into its microprocessor according to each type of steel, temperature and residence time.

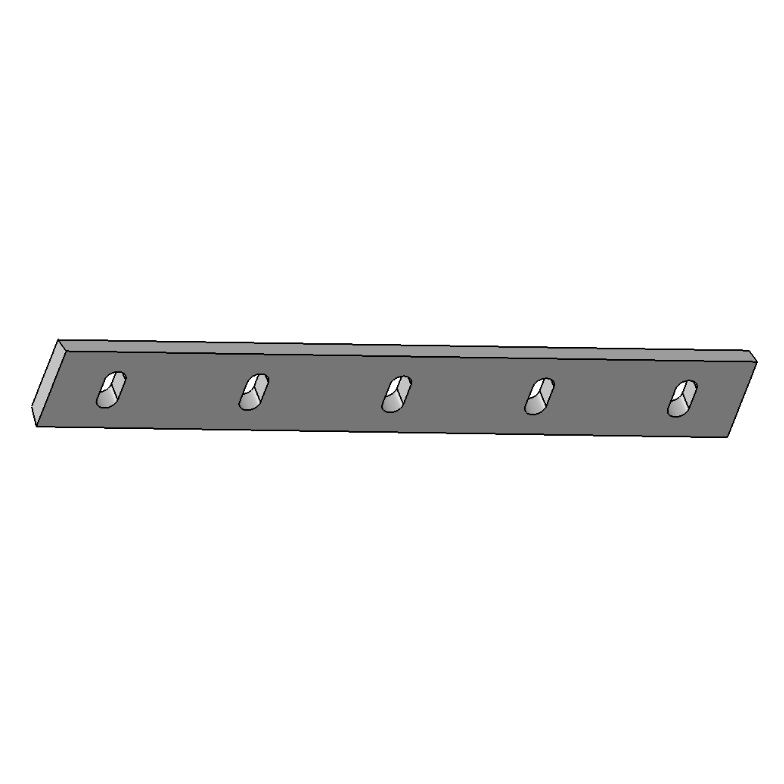

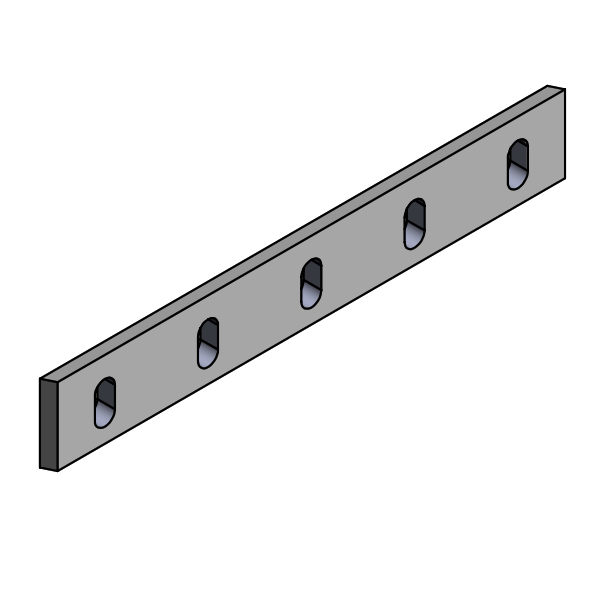

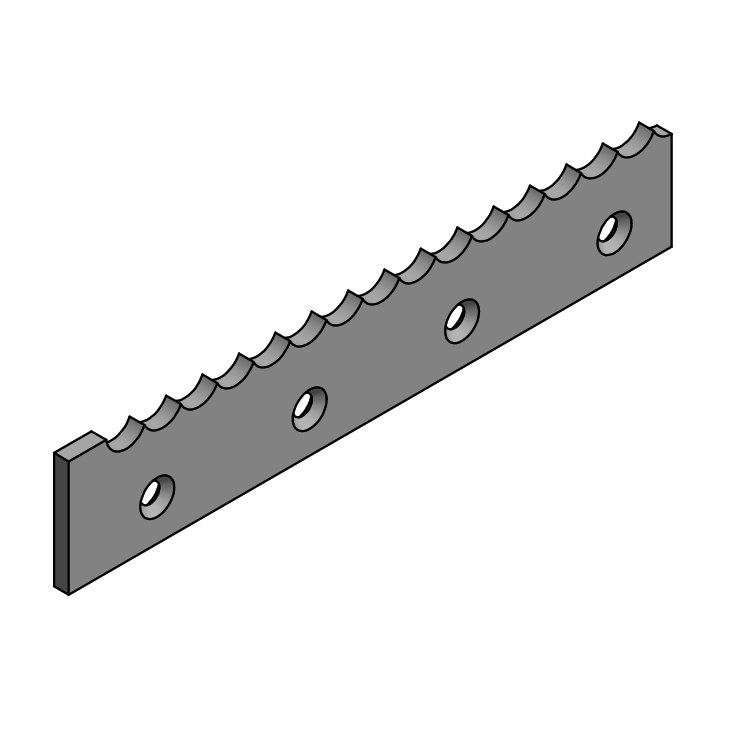

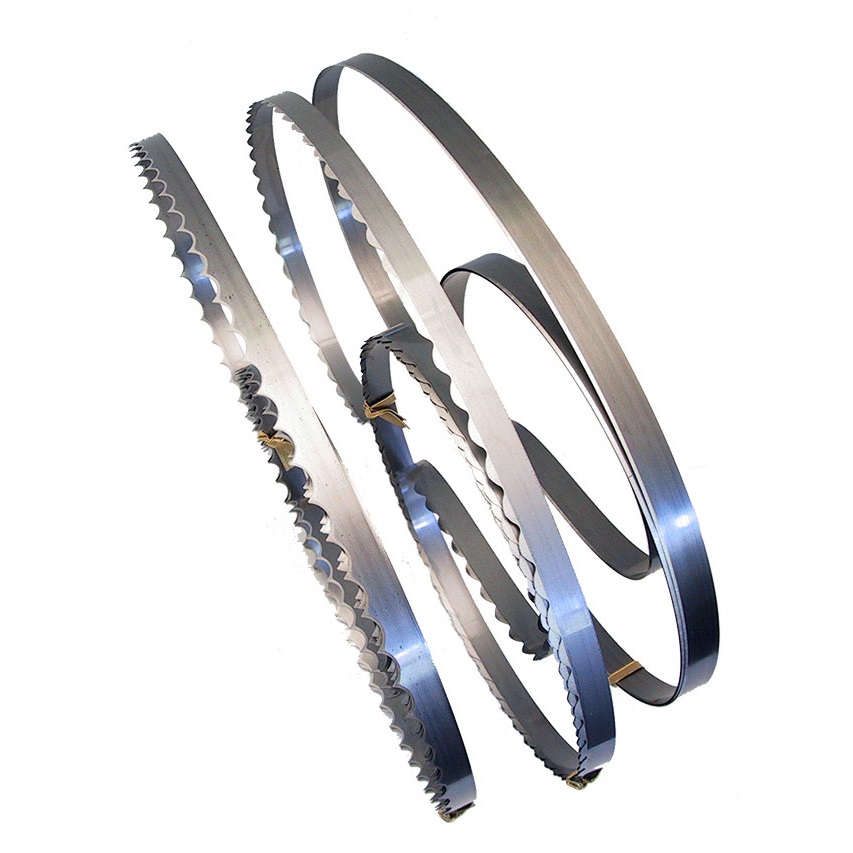

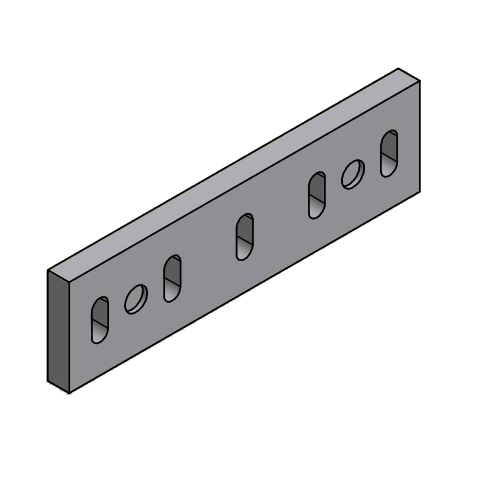

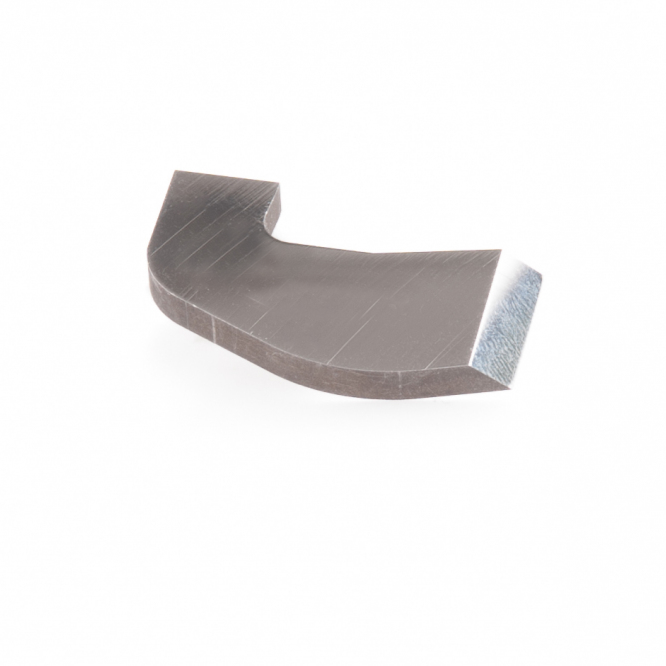

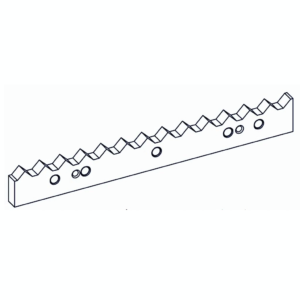

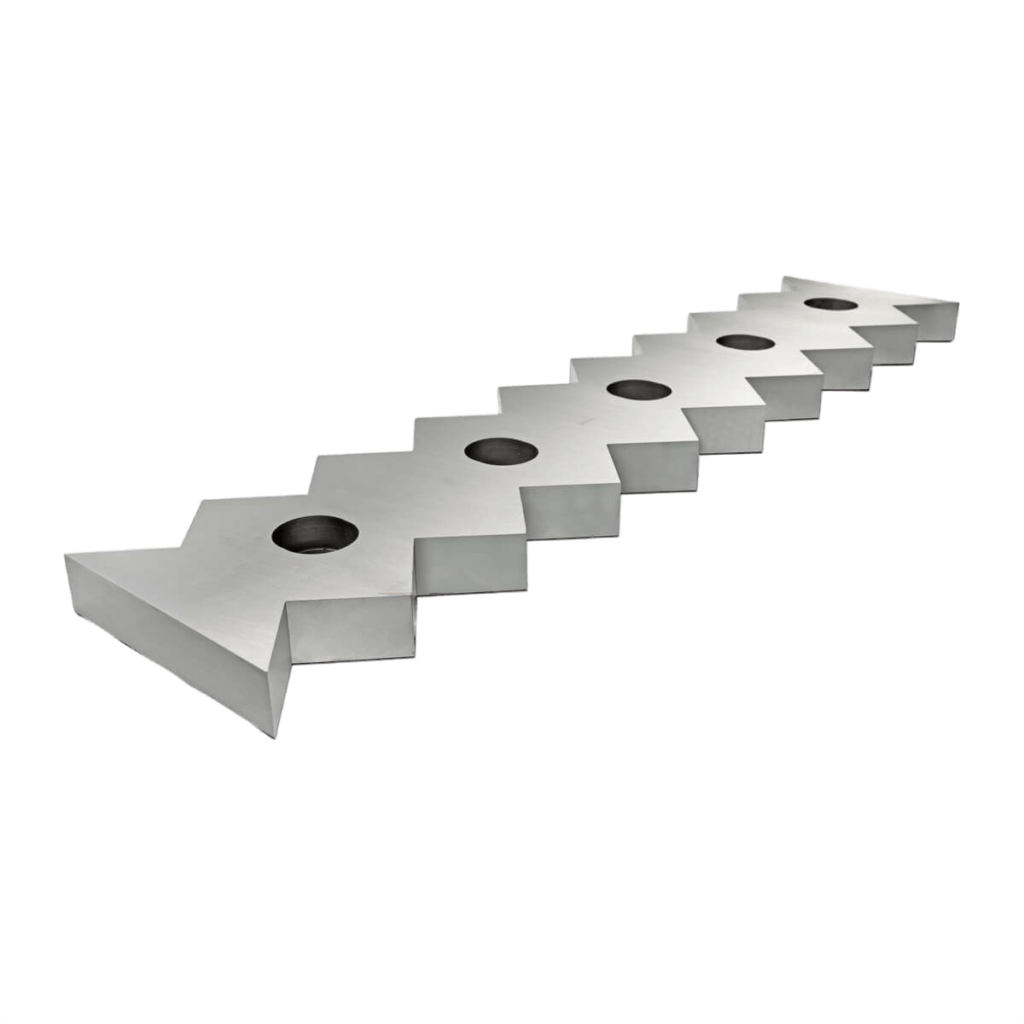

Grinding and sharpening

After heat treatment, all blades undergo a grinding process to achieve precision, tolerance and excellent finish. The next step is the preparation of the cutting edges, which is carried out using the most advanced technique that prevents structural changes to the steel in the sharpened area and allows for the perfect cut.

Quality control

After completing the manufacturing process, our quality department carries out an exhaustive dimensional and hardness control.

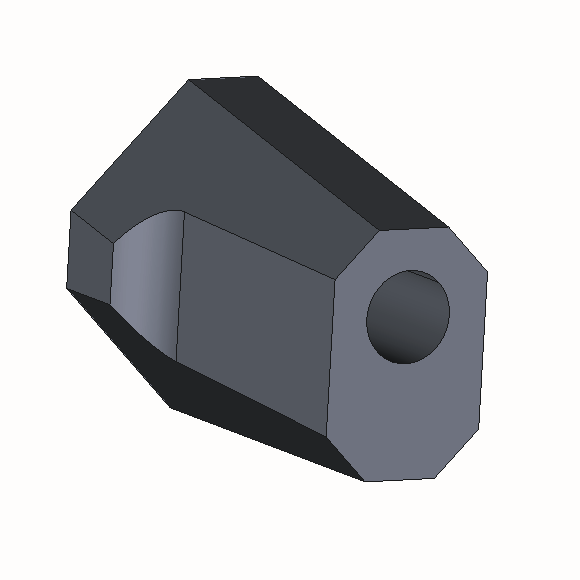

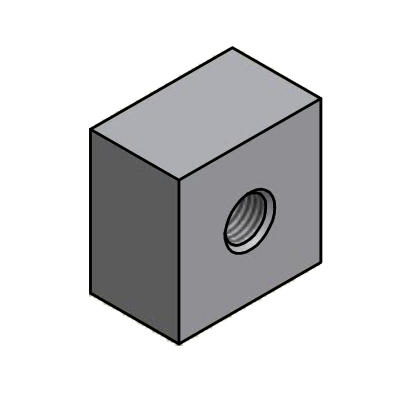

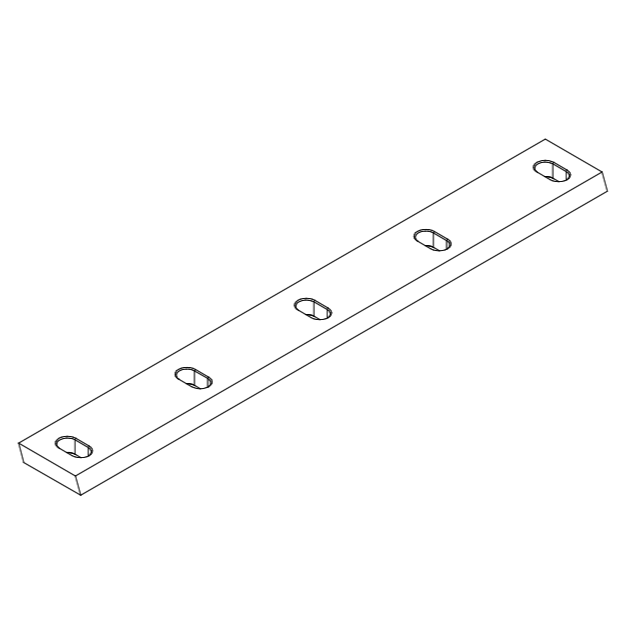

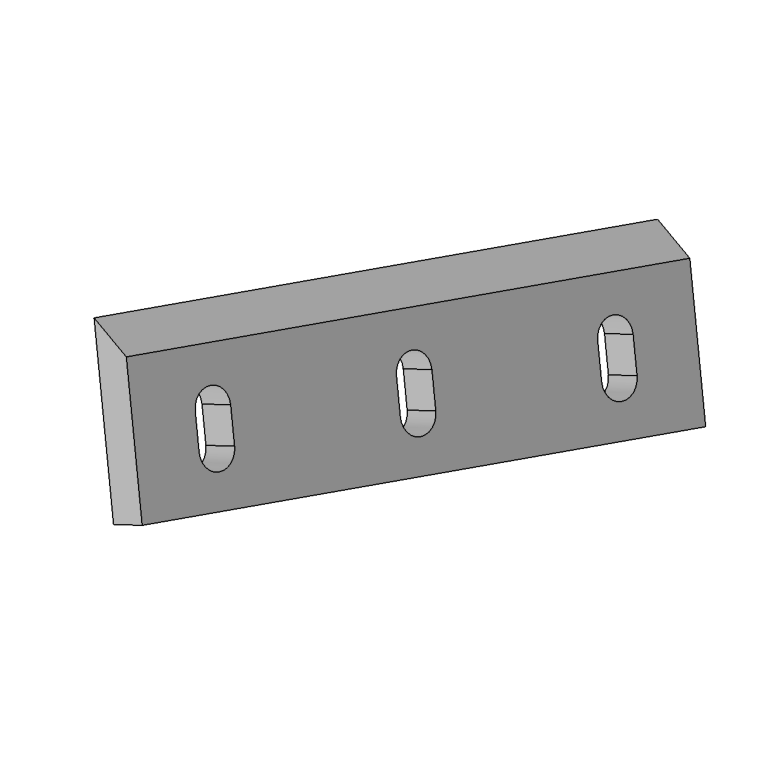

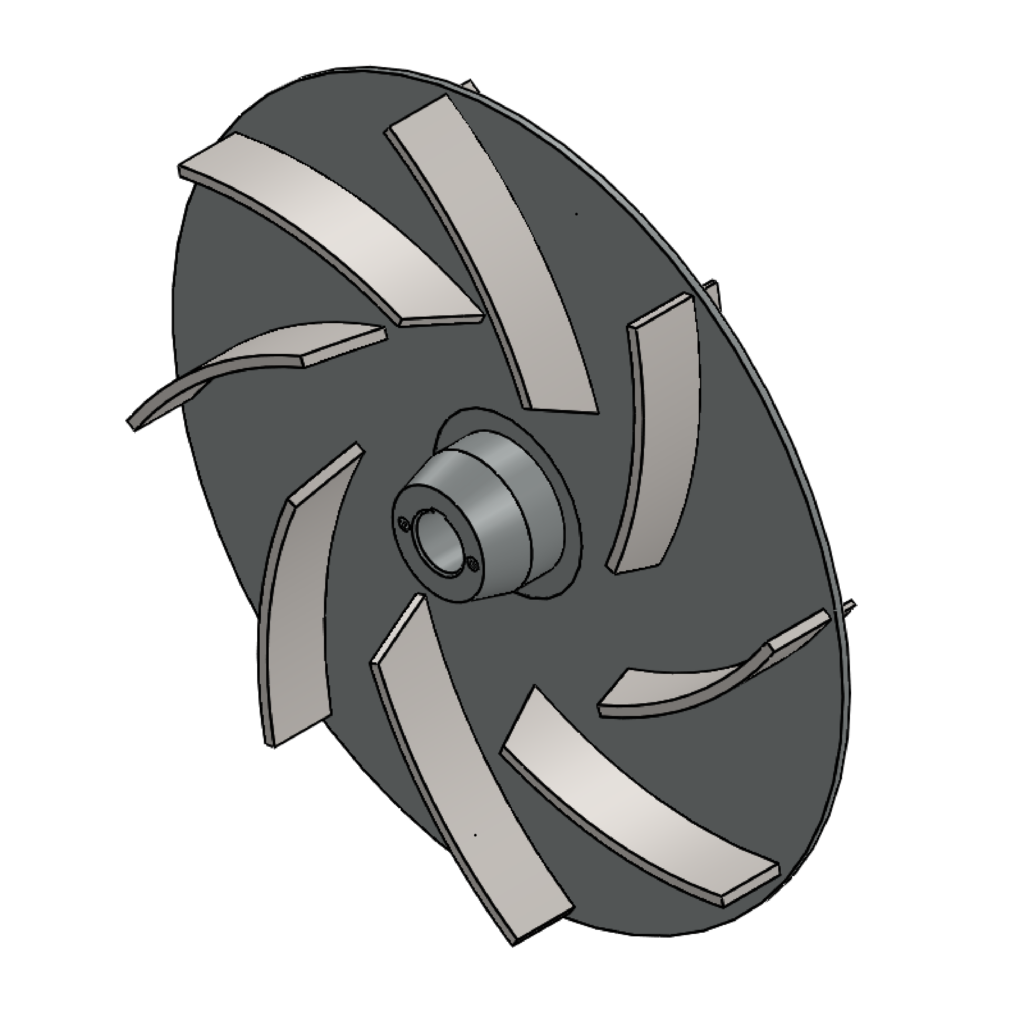

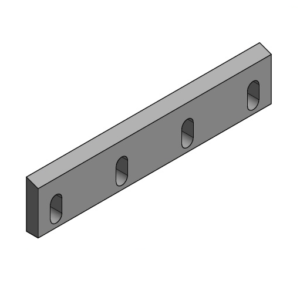

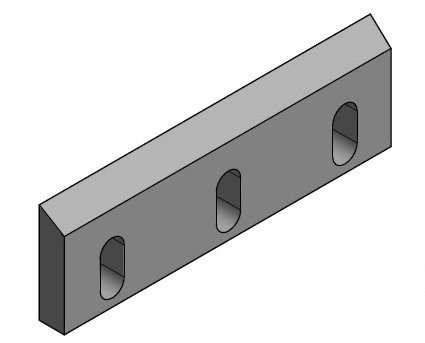

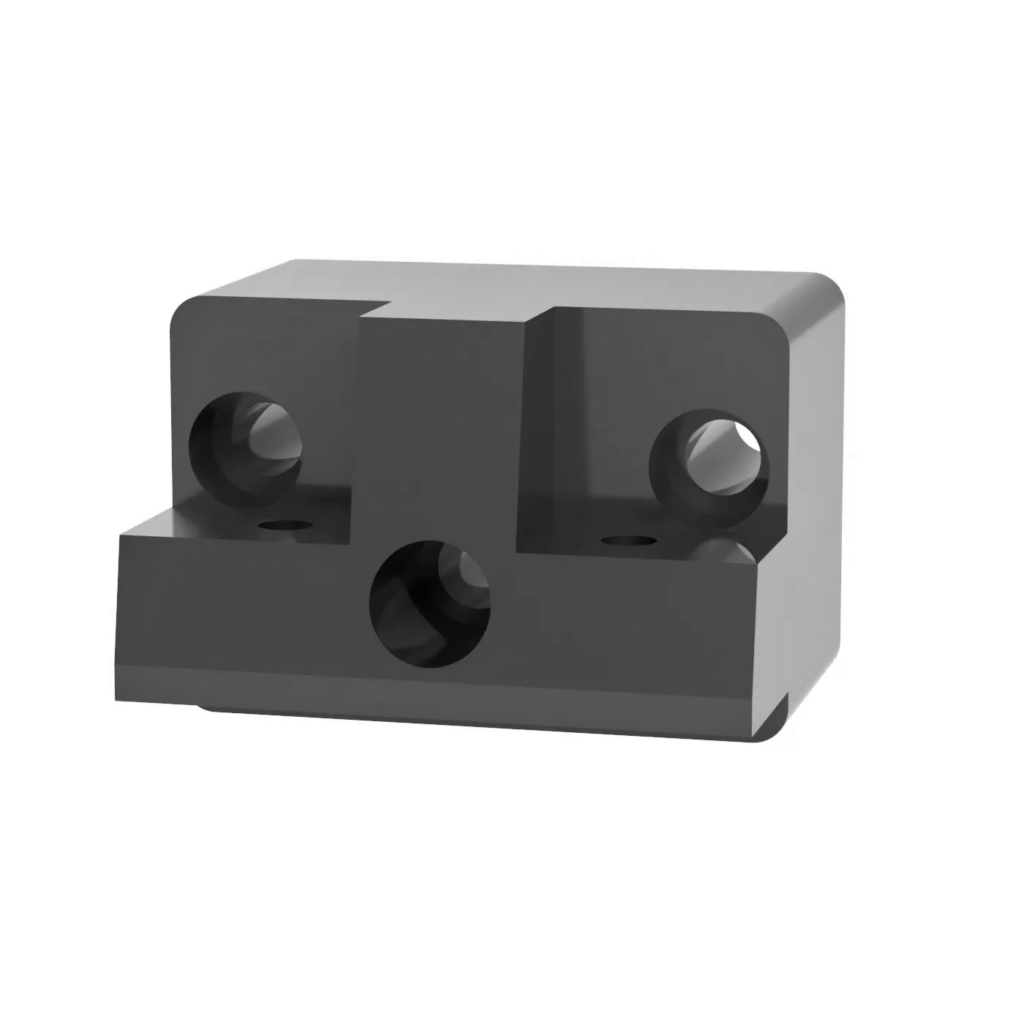

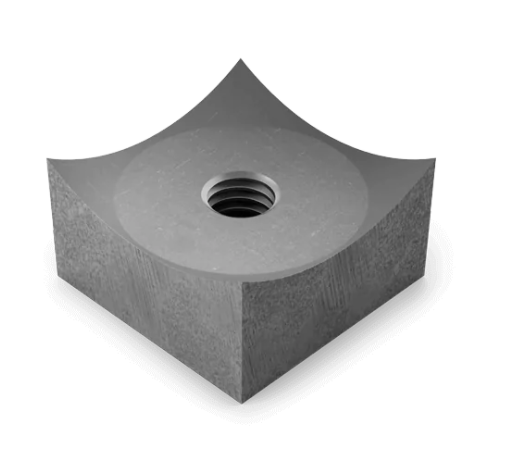

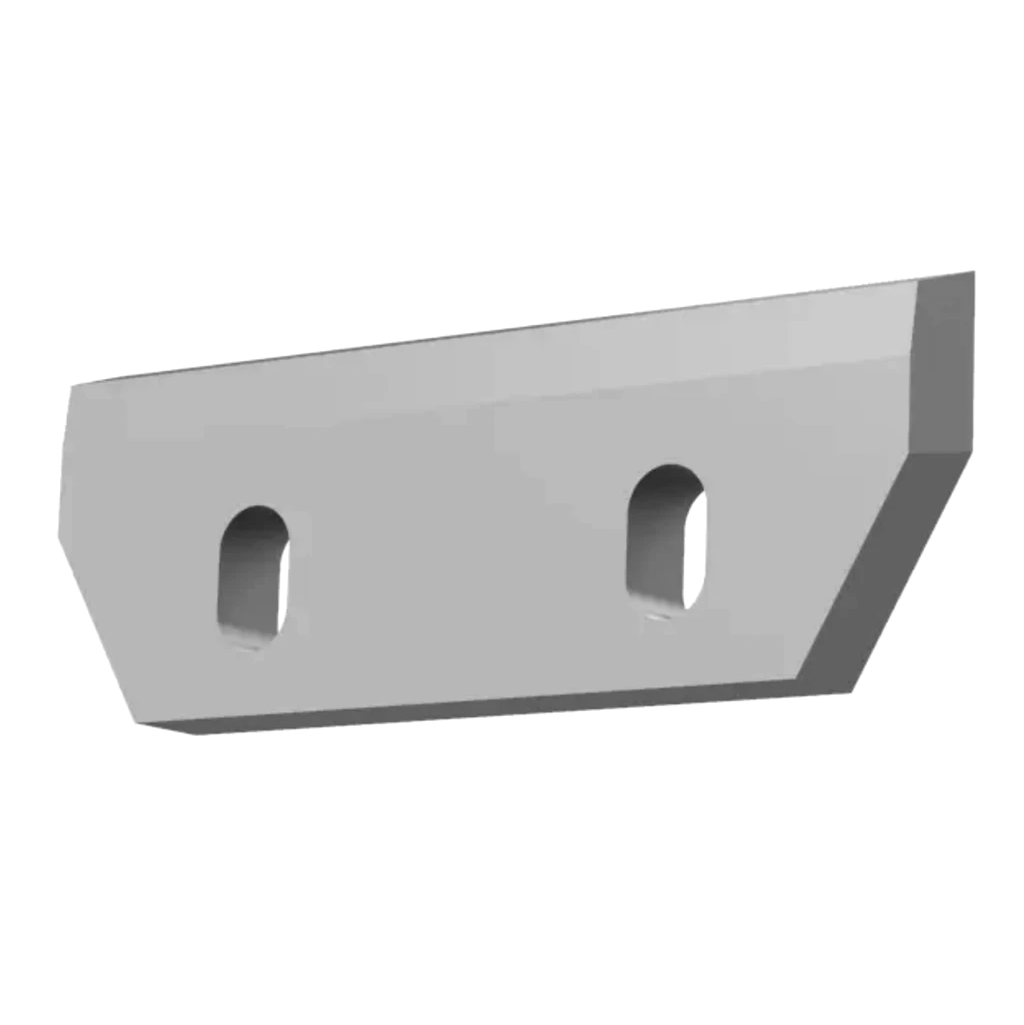

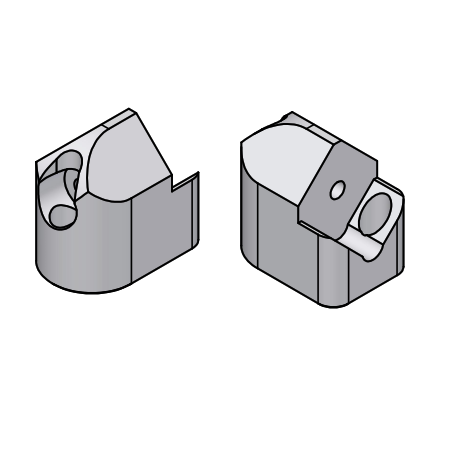

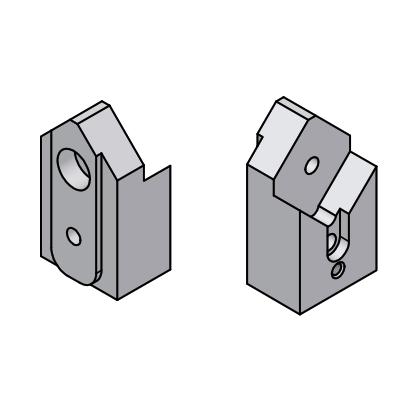

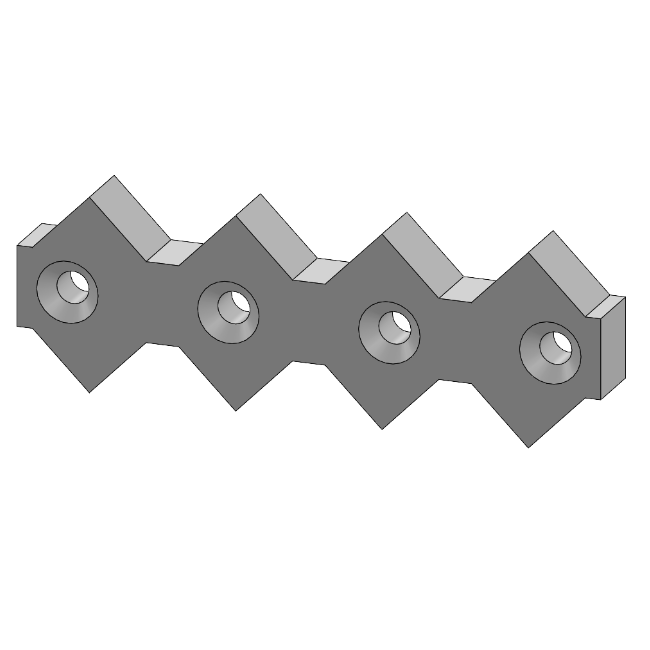

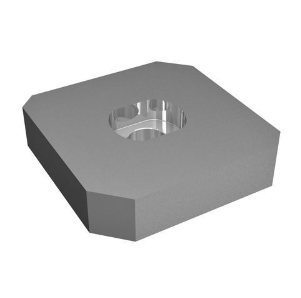

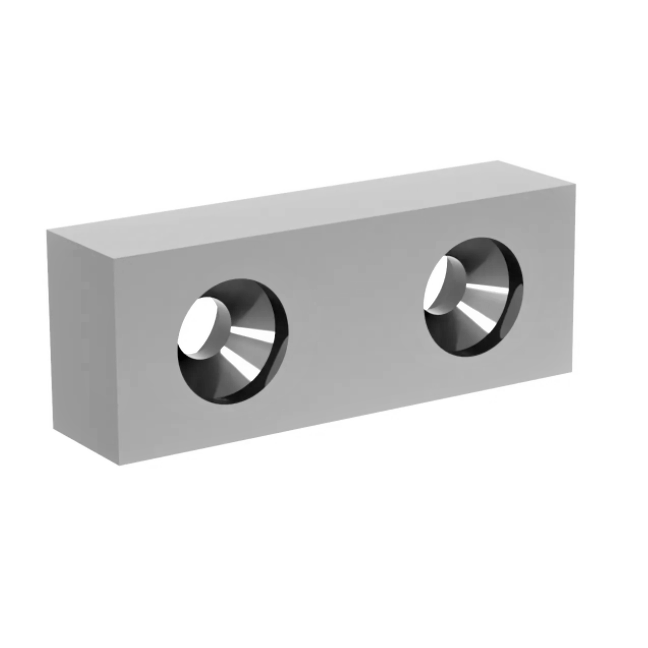

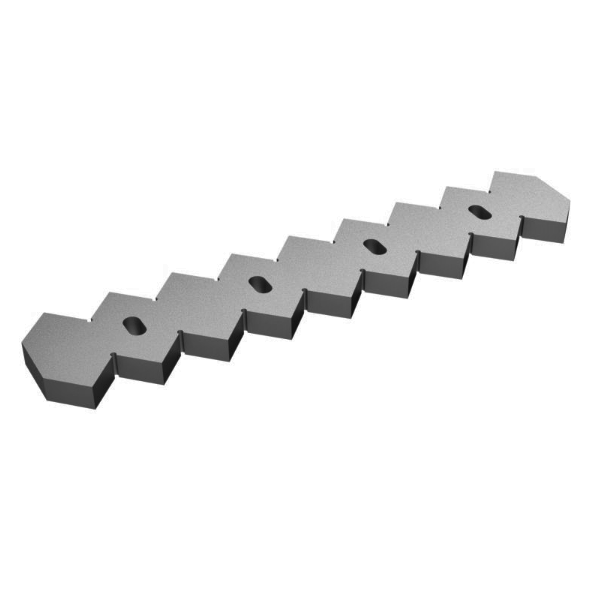

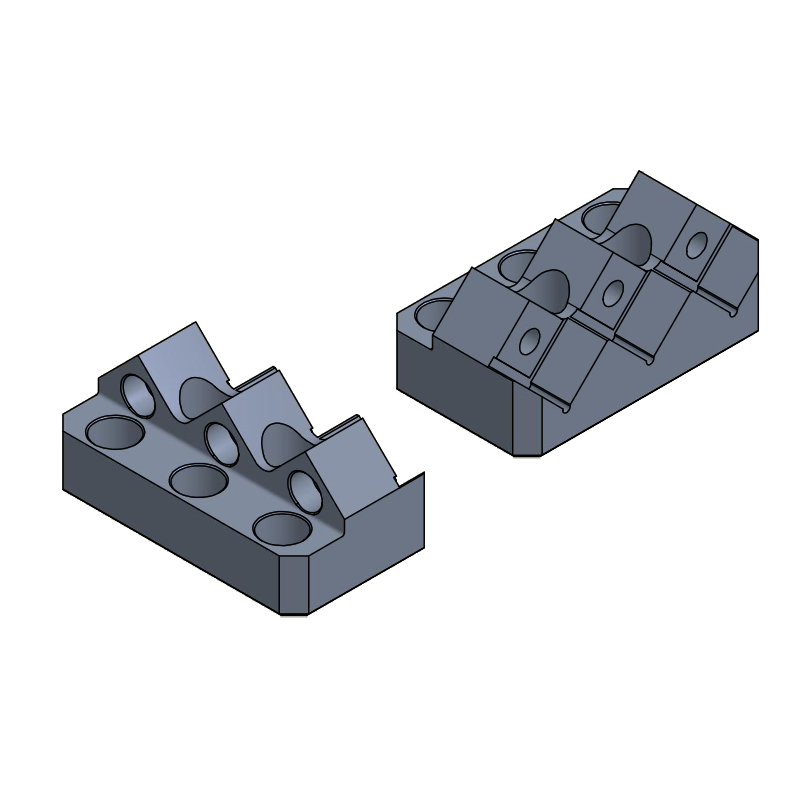

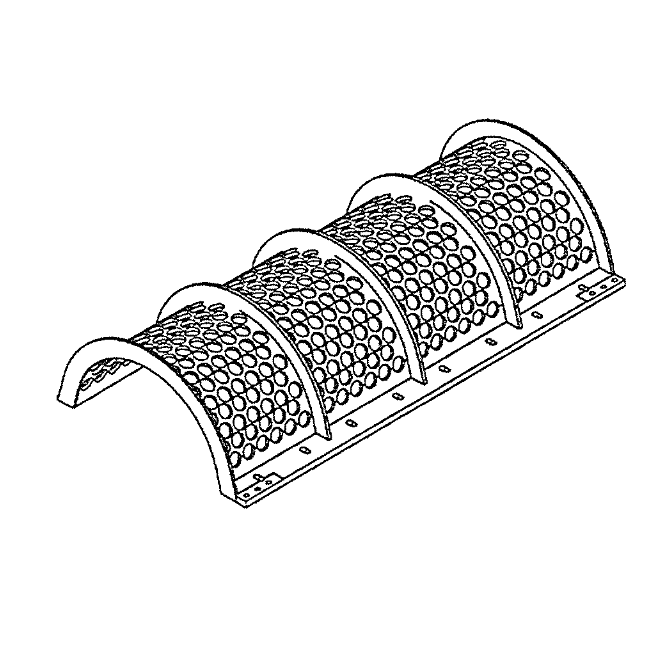

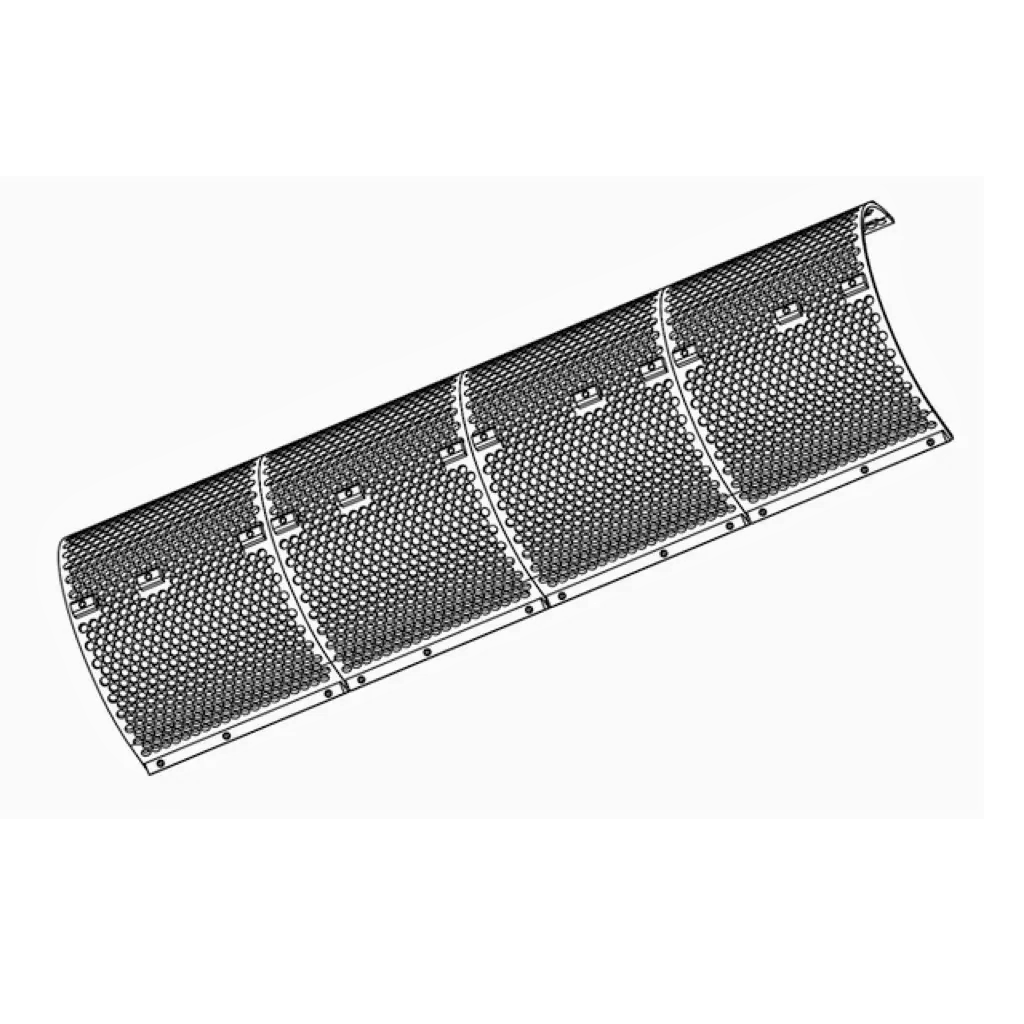

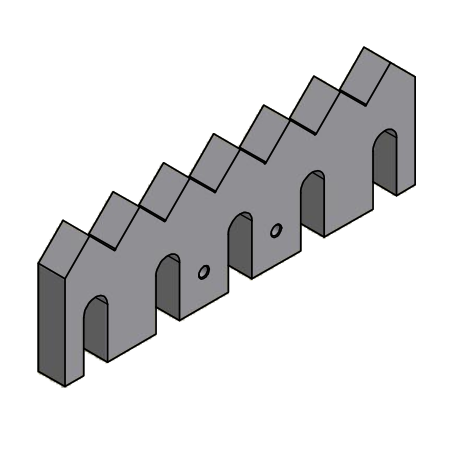

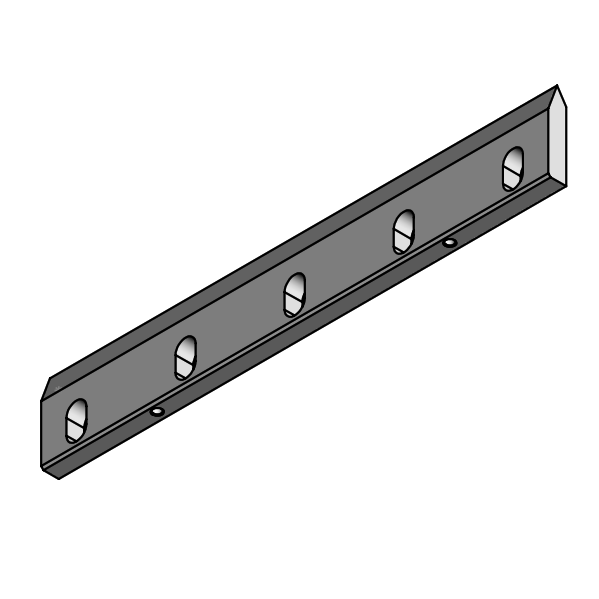

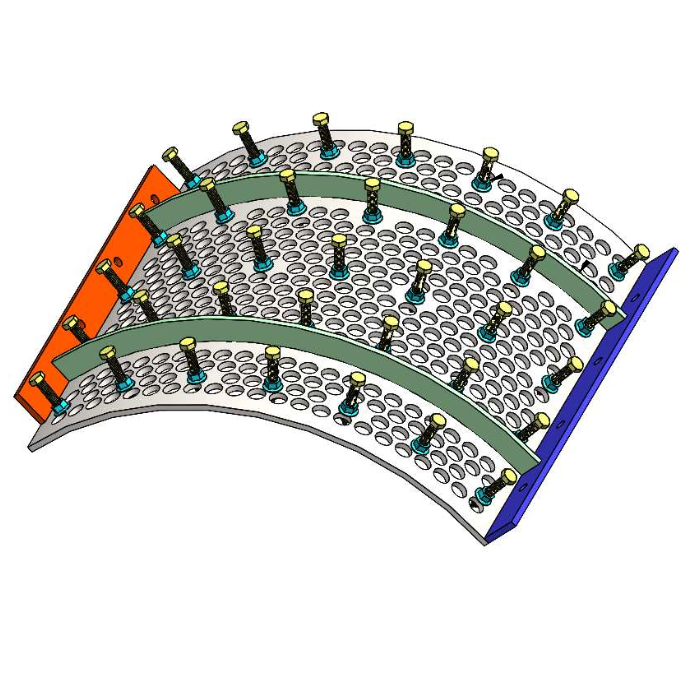

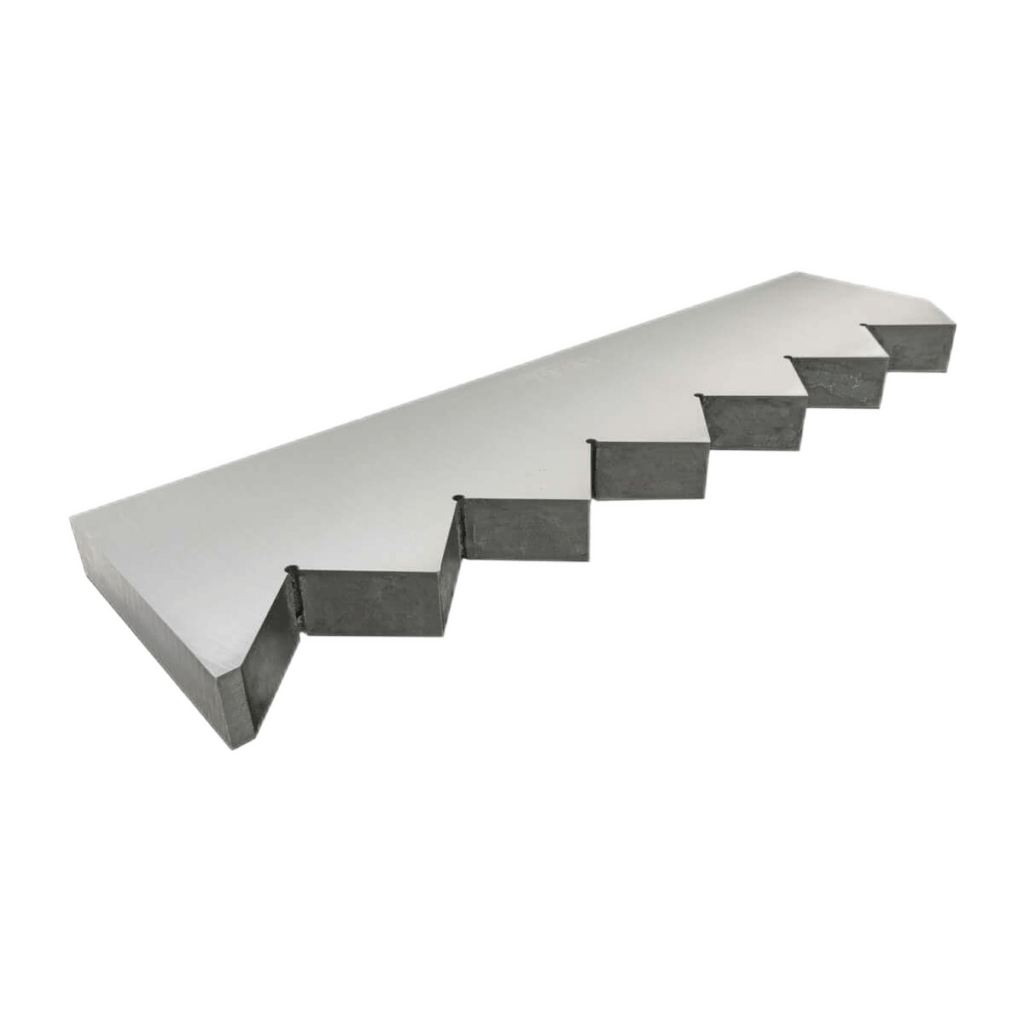

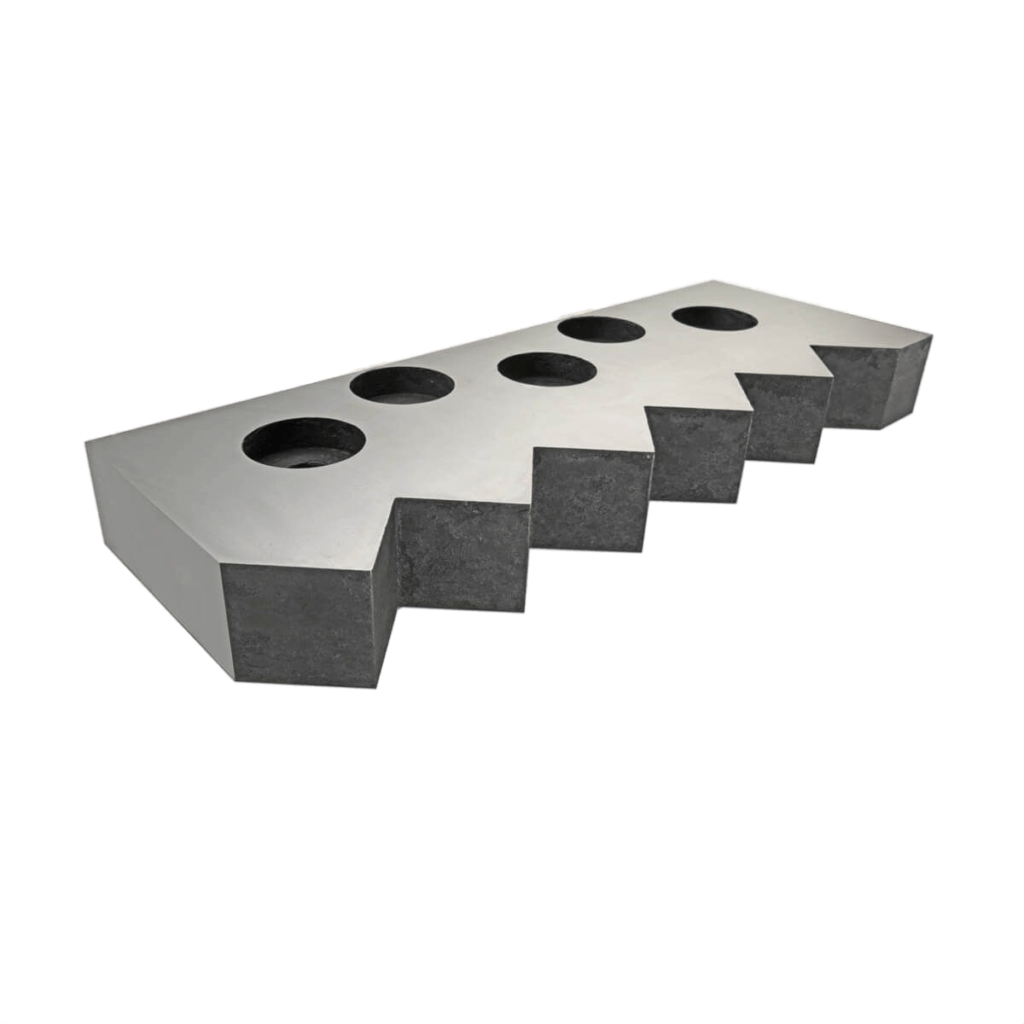

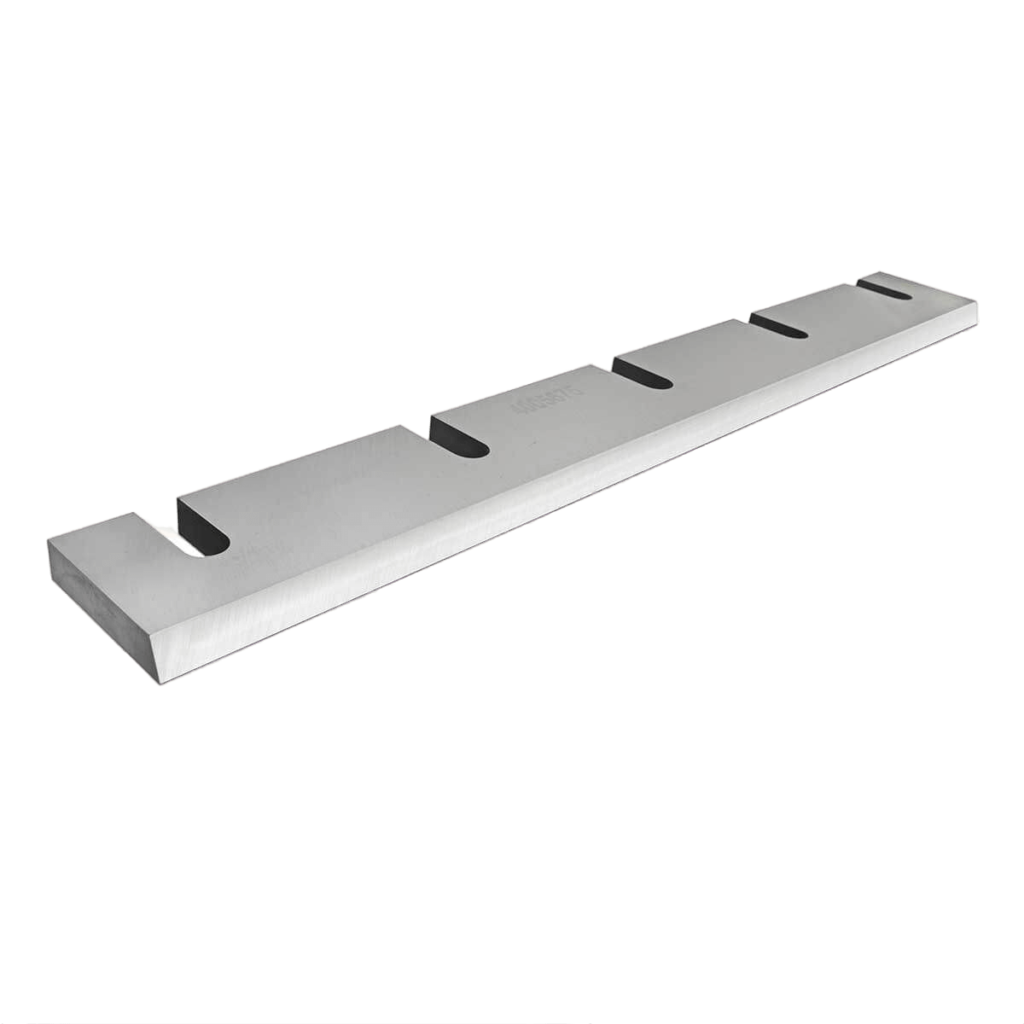

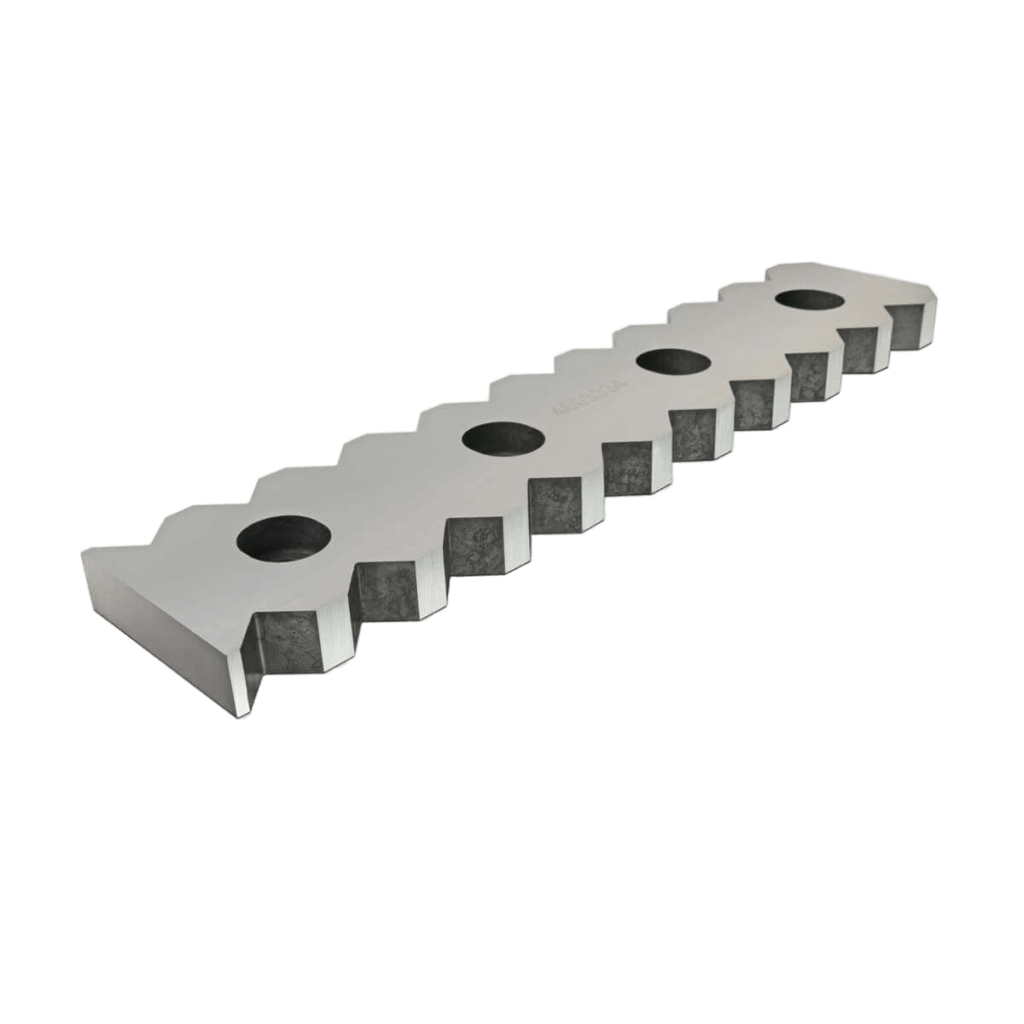

HIGH PERFORMANCE INDUSTRIAL KNIVES AND WEAR PARTS

FOR SHREDDING AND CUTTING MACHINERY

TRUSTED SUPPLIER

20

YEARS OF EXPERIENCE

100%

CERTIFIED QUALITY

27

EXPORT COUNTRIES